Hi all,

I've got a 28X1 running off a 5V regulated supply. I have two 9-12V DC motors with their respective gearboxes. I also have two smallish bipolar stepper motors.

Firstly, for a small line following robot I'm guessing DC is the way to go? Would you agree?

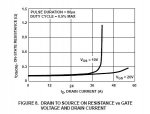

Secondly, what's the best way to go about controlling them with variable speed? The X1 can do two PWMOUTs (can it not?) so would PWMing a FET for each motor be my best bet? Or can anyone recommend (is there) a PWM controller that I can communicate with via serial/I2C etc? Is a MOSFET driver a necessity here? Bear in mind I have never really used FETs before so I don't know much about them.

I would like as much control over the the motors' speed as possible.

Thanks for any input,

*j

I've got a 28X1 running off a 5V regulated supply. I have two 9-12V DC motors with their respective gearboxes. I also have two smallish bipolar stepper motors.

Firstly, for a small line following robot I'm guessing DC is the way to go? Would you agree?

Secondly, what's the best way to go about controlling them with variable speed? The X1 can do two PWMOUTs (can it not?) so would PWMing a FET for each motor be my best bet? Or can anyone recommend (is there) a PWM controller that I can communicate with via serial/I2C etc? Is a MOSFET driver a necessity here? Bear in mind I have never really used FETs before so I don't know much about them.

I would like as much control over the the motors' speed as possible.

Thanks for any input,

*j