plasmaninjaa

Member

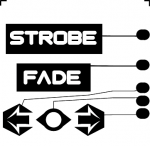

Hey guys, some of you might remember a while back the endless questions I had on topics such

as RGB leds, serial communication, frequency adjustment, circuit designs etc...

I would like to officially present to you the result of all that hard work! https://www.youtube.com/watch?v=CapW1XaoJUU

It was 2 years of struggling and asking questions. As a high school student back when I started, I had zero schooling on electronics (and still don't!).

But with the help from this community, I was able to overcome all the complications and questions I had,

to finally have a fully working prototype that will be taken to market!

Cheers and thanks! You know who you are.

(if you have any questions about the design, feel free to ask)

as RGB leds, serial communication, frequency adjustment, circuit designs etc...

I would like to officially present to you the result of all that hard work! https://www.youtube.com/watch?v=CapW1XaoJUU

It was 2 years of struggling and asking questions. As a high school student back when I started, I had zero schooling on electronics (and still don't!).

But with the help from this community, I was able to overcome all the complications and questions I had,

to finally have a fully working prototype that will be taken to market!

Cheers and thanks! You know who you are.

(if you have any questions about the design, feel free to ask)