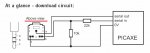

Hello, I am going to set up a picaxe circuit on a breadboard including a stereo jack for computer interface.

I see you can buy pre-made Picaxe breadboard Programming adaptors that include the stereo jack and they also have a jumper arrangement to alternate between programming download and output.

Than again, I have also see guys just wire up their own stereo jacks direct to the picaxe pins on the breadboard. They dont seem to have this jumper arrangement to alternate between download and output mode.

My question is, is this jumper necessary or can I just leave it out on my breadboard.

Thanks for any help.

I see you can buy pre-made Picaxe breadboard Programming adaptors that include the stereo jack and they also have a jumper arrangement to alternate between programming download and output.

Than again, I have also see guys just wire up their own stereo jacks direct to the picaxe pins on the breadboard. They dont seem to have this jumper arrangement to alternate between download and output mode.

My question is, is this jumper necessary or can I just leave it out on my breadboard.

Thanks for any help.