AS some of you know i have been working on a little project involving a stepper motor. I have made a bit of theortical progress but life is stopping me buy stuff for thing like the motor and ahaing a custom threaded bar cut.

but back to the theory and design, i have been looking at micro step controllers using something like the TB6560 or TH6064 when at work and with a little inspiration from stpperworld and idea hit me like a freight train.

why not have the wave patern pre-programmed into a picaxe. then i realised my analogue electronic isnt so hot

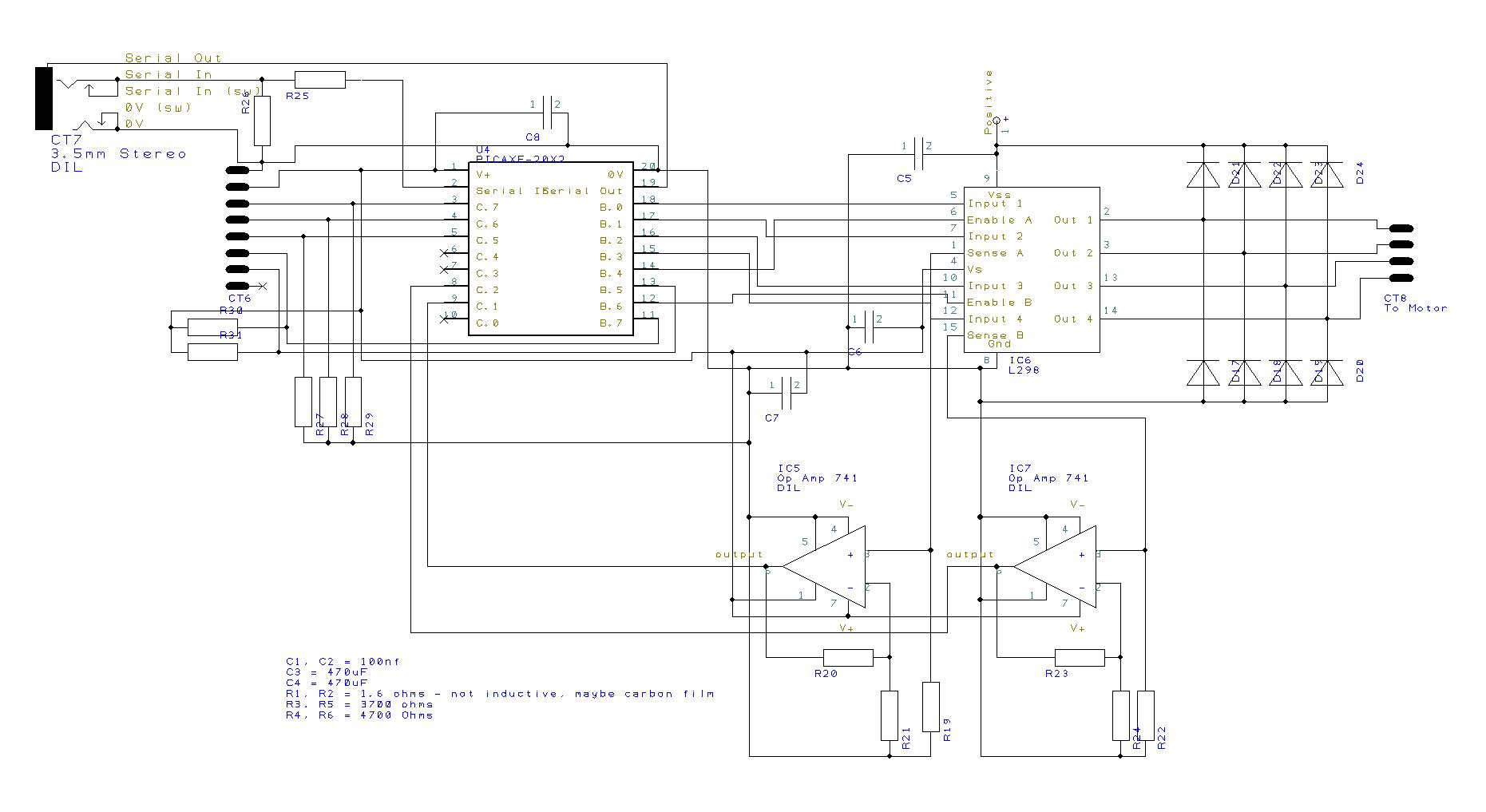

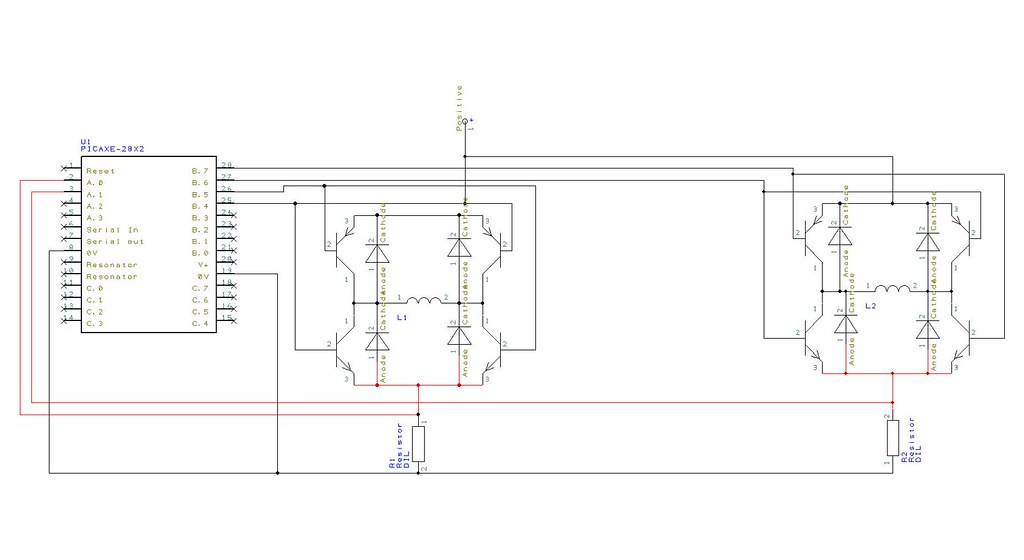

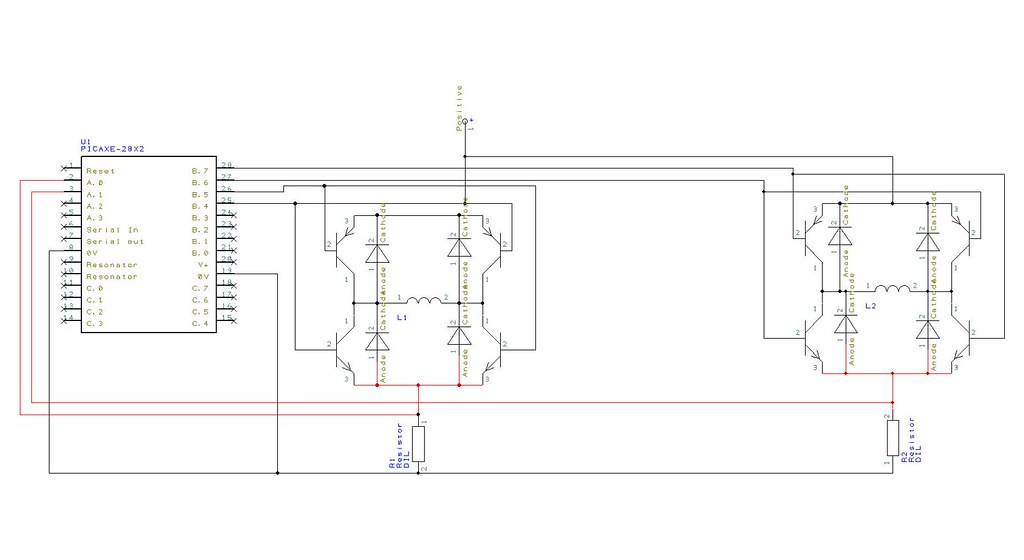

circuit so far

Driver 0.1 by f2268d215cc925918731918f4efa0289, on Flickr

now as you can there is no comparitor (should go on the red wires, one for each phase of the motor), this is the problem as it will be needed to stop putting too much voltage into the picaxe if you use a higher voltage motor, or you will loose resolution fro lower voltage. any ideas on the best type of circuit i should use, i know it will most likely by op-amp with some hysterisis but it will need to keep within 0-5v and follow the voltage arc from the phase of the motor

it a very rough start any ideas or testing or error i have made feel free to say something. the biggest thing is, will it work, and if so how well

http://www.stepperworld.com/Tutorials/pgMicrostepping.htm

but back to the theory and design, i have been looking at micro step controllers using something like the TB6560 or TH6064 when at work and with a little inspiration from stpperworld and idea hit me like a freight train.

why not have the wave patern pre-programmed into a picaxe. then i realised my analogue electronic isnt so hot

circuit so far

Driver 0.1 by f2268d215cc925918731918f4efa0289, on Flickr

now as you can there is no comparitor (should go on the red wires, one for each phase of the motor), this is the problem as it will be needed to stop putting too much voltage into the picaxe if you use a higher voltage motor, or you will loose resolution fro lower voltage. any ideas on the best type of circuit i should use, i know it will most likely by op-amp with some hysterisis but it will need to keep within 0-5v and follow the voltage arc from the phase of the motor

Code:

#picaxe 28x2

symbol L0 = b0

symbol U0 = b1

symbol L1 = b2

symbol U1 = b3

symbol PhaseA = b5

symbol PhaseB = b6

symbol PhAlook = b7

symbol PhBlook = b8

symbol PhAval = b9

symbol PhBval = b10

symbol clk = pinc.0

symbol direct = pinc.1

intit:

setint %00000001, %00000001 'set interupt

'now set sine wave lookup value

let phalook = 0

let phblook = phalook + 6

main:

'now get voltage value from ech phase

readadc 0, phaseA

readadc 1, phaseB

'now check if phase A is within tolerence

if phaseA < L0 or phasea > U0 then

if Phasea < L0 then

'switch on phase a

else

'swithc of phase

end if

end if

'now check if phase B is within tolerence

if phaseB < L0 or phaseb > U0 then

if PhaseB < L0 then

'switch on phase a

else

'swithc of phase

end if

end if

goto main

interrupt:

pause 5000

#rem

step |% |Voltage |ADC value |ADC

----------------------------------------

0 |100.00%| 5 |256 |256

1 | 98.10%| 4.905 |251.136 |251

2 | 92.40%| 4.62 |236.544 |237

3 | 83.10%| 4.155 |212.736 |213

4 | 70.10%| 3.505 |179.456 |179

5 | 55.50%| 2.775 |142.08 |142

6 | 38.20%| 1.91 |97.792 |98

7 | 19.50%| 0.975 |49.92 |50

8 | 0.00% | 0 |0 0

Figures Obtained from stepperworld.com

#endrem

'check direction

if direct = 0 then

inc phalook

inc phalook

else

dec phalook

dec phblook

end if

'over/underflow protection needed

'lookup sine wave values

lookup phalook, (256,251,237,213,179,142,98,50),phaval

let L0 = phaval - 10

let U0 = phaval + 10

lookup phblook, (256,251,237,213,179,142,98,50),phbval

let L1 = phbval - 10

let U1 = phbval + 10

'coil change and reducing votlage needed.

setint %00000001, %00000001

returnhttp://www.stepperworld.com/Tutorials/pgMicrostepping.htm