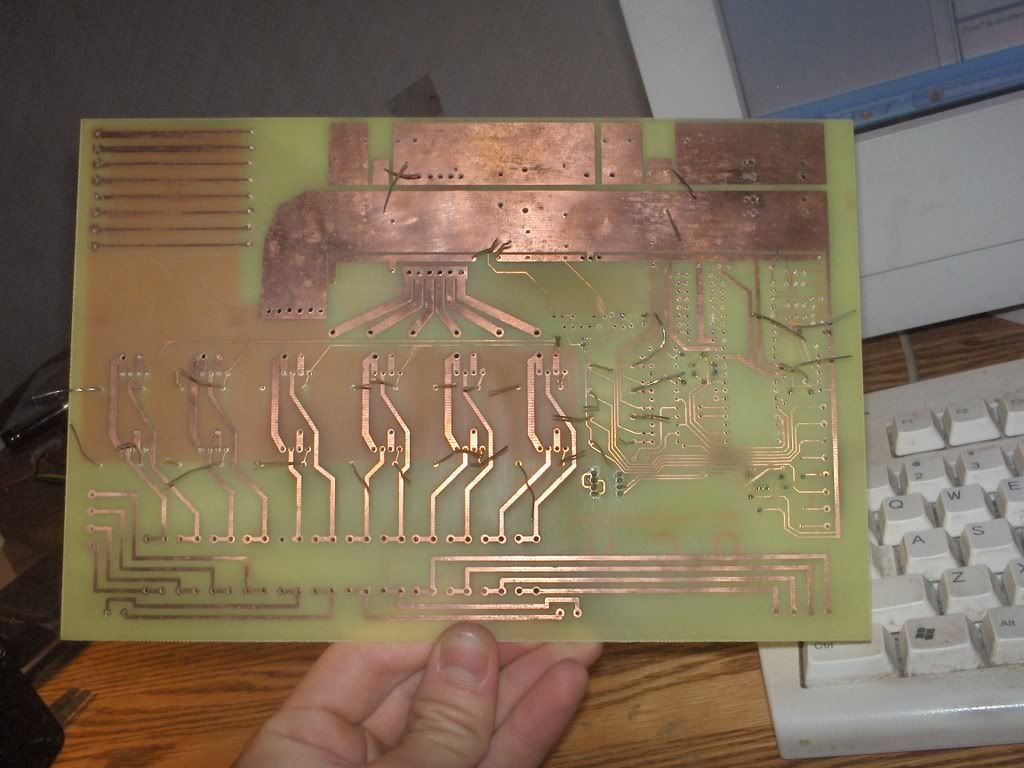

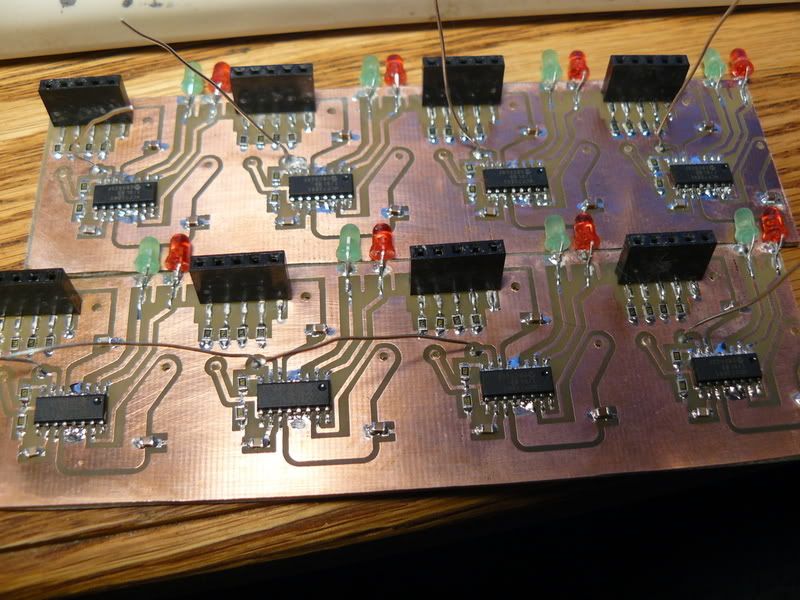

I'm making an LED flashlight with 6 10440 size (AAA) cells. You can get many cells these days with protection circuits, unfortunately these smaller ones aren't available with onboard protection. I've already made a switching CC LED driver to run from 6 cells.

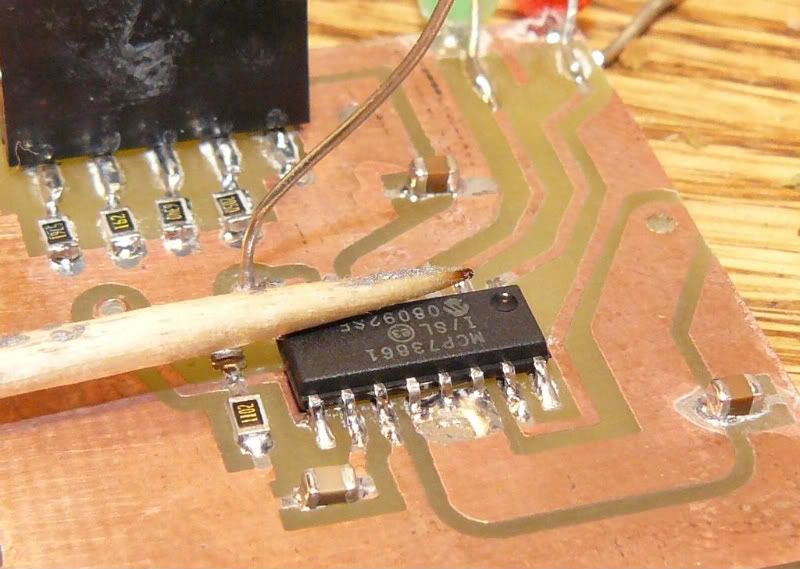

I've also already built a Li-Ion charger that's very accurate, so I don't need to worry about overvoltage, I'm not making a battery pack that will be charged in series. I just need to make sure the batteries don't drain too far in the device. I'd like to cut them off at ~2.75V.

My initial idea is to use a switching 5V reg to supply a picaxe, and since space is a concern (working with a 23mm bore) I want to use the 18pin SOIC picaxe, it's the only SMT picaxe that the Canadian picaxe supplier has, but I could also fit a 28pin SOIC if I needed to.

I'd like to keep the battery drain as low as possible, and I'd like to also add a hall effect sensor to read the current to the LEDs and display it on a 7 segment LED display. I don't have a lot of room so I'll only use 2 segments to display the first 2 digits of the 100-999mA. I suppose I could go LCD, but I think that's more complicated than I'm up for. This stuff I'll read more about though.. just giving reference for what else I'll want to do with the picaxe.

My main goal here is to be able to monitor the voltage of each cell, and just use something like a NC relay to the LEDs, blink it open 3 times to warn when the batteries are depleted. I did a search for battery monitoring and saw a few different methods being discussed. I suppose it would even be safe enough to monitor 3 sets of 2 cells in series, then I could get away with 1 chip as I would have enough ADCs.

I'm looking for input on how easiest I can read a dying voltage and simply send a signal to a relay while being least wasteful with the batteries. I don't suppose you can use the digital inputs as a ground for reference to individual batteries? Then I could just tie ADCs to corresponding grounds and read the voltage? I'm not sure if that's possible, I'm still very new with the whole picaxe thing.

I've also already built a Li-Ion charger that's very accurate, so I don't need to worry about overvoltage, I'm not making a battery pack that will be charged in series. I just need to make sure the batteries don't drain too far in the device. I'd like to cut them off at ~2.75V.

My initial idea is to use a switching 5V reg to supply a picaxe, and since space is a concern (working with a 23mm bore) I want to use the 18pin SOIC picaxe, it's the only SMT picaxe that the Canadian picaxe supplier has, but I could also fit a 28pin SOIC if I needed to.

I'd like to keep the battery drain as low as possible, and I'd like to also add a hall effect sensor to read the current to the LEDs and display it on a 7 segment LED display. I don't have a lot of room so I'll only use 2 segments to display the first 2 digits of the 100-999mA. I suppose I could go LCD, but I think that's more complicated than I'm up for. This stuff I'll read more about though.. just giving reference for what else I'll want to do with the picaxe.

My main goal here is to be able to monitor the voltage of each cell, and just use something like a NC relay to the LEDs, blink it open 3 times to warn when the batteries are depleted. I did a search for battery monitoring and saw a few different methods being discussed. I suppose it would even be safe enough to monitor 3 sets of 2 cells in series, then I could get away with 1 chip as I would have enough ADCs.

I'm looking for input on how easiest I can read a dying voltage and simply send a signal to a relay while being least wasteful with the batteries. I don't suppose you can use the digital inputs as a ground for reference to individual batteries? Then I could just tie ADCs to corresponding grounds and read the voltage? I'm not sure if that's possible, I'm still very new with the whole picaxe thing.