WHITEKNUCKLES

New Member

I wanted to repeatedly lift a 2 Lbs weight to a variable preset height of up to 12 inches using a 3 inch diameter roller in less than 1.5 seconds when switched.

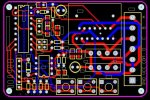

Available was a 1.8 degree, 2.6 Ohm, 4Nm stepper motor and a 2A stepper controller containing a L298n driver and an 18 pin micro, both from ebay.

At the relatively fast stepping rate the current would be within the capability of the L298 but there is no access to the enable pins on this controller so when stationary the current would be excessive. Happily the installed 18 pin micro used pins 17,18,1,2 for the motor and 7,8,9 for switched inputs with pull-ups and this accorded well with the Picaxe 18M2.

Removing one pull-up made an adc pin available for a potentiometer for the number of steps and one input starts the stepping sequence that ends in outputting 0000 cutting power to the motor. An adaptor was made to allow a sm 7805l to replace the original onboard memory chip eliminating the previous need for a separate 5V supply.

At 1.2 second lift and 3 sec drop the heatsink reaches a steady 40 degrees in an ambient of 20 after 25 minutes running.

This board is an independently functioning stepper motor controller available for very little more than the bare L298 chip price in the UK and a doddle to change to an 18M2.

Dave

Available was a 1.8 degree, 2.6 Ohm, 4Nm stepper motor and a 2A stepper controller containing a L298n driver and an 18 pin micro, both from ebay.

At the relatively fast stepping rate the current would be within the capability of the L298 but there is no access to the enable pins on this controller so when stationary the current would be excessive. Happily the installed 18 pin micro used pins 17,18,1,2 for the motor and 7,8,9 for switched inputs with pull-ups and this accorded well with the Picaxe 18M2.

Removing one pull-up made an adc pin available for a potentiometer for the number of steps and one input starts the stepping sequence that ends in outputting 0000 cutting power to the motor. An adaptor was made to allow a sm 7805l to replace the original onboard memory chip eliminating the previous need for a separate 5V supply.

At 1.2 second lift and 3 sec drop the heatsink reaches a steady 40 degrees in an ambient of 20 after 25 minutes running.

This board is an independently functioning stepper motor controller available for very little more than the bare L298 chip price in the UK and a doddle to change to an 18M2.

Dave

Attachments

-

117.3 KB Views: 137