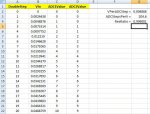

Would someone kindly advise me IN SIMPLE TERMS the difference between readadc and readadc10....I understand that it returns 8 or 10 bits but when / why would you use each ?

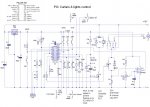

For an external light controller I am trying to read the light level using an LDR connected to pin 1 of a PICAXE 18X (I need extra in / out so the 18X is required) and 0 to 255 is not giving me enough range - the required levels are around 10 to 20.

Am I wrong in assuming that readadc10 would give me a greater range ?

I am using a PICAXE 18X

Thanks

main:

SYMBOL dark_level = 10

SYMBOL light_level = 20

check: readadc 2,b0 ' ADC input 2 - dark sensor,PIC pin 1, read into b0

if b0=<dark_level then dark ' condition if dark

if b0>=light_level then light ' condition if light

For an external light controller I am trying to read the light level using an LDR connected to pin 1 of a PICAXE 18X (I need extra in / out so the 18X is required) and 0 to 255 is not giving me enough range - the required levels are around 10 to 20.

Am I wrong in assuming that readadc10 would give me a greater range ?

I am using a PICAXE 18X

Thanks

main:

SYMBOL dark_level = 10

SYMBOL light_level = 20

check: readadc 2,b0 ' ADC input 2 - dark sensor,PIC pin 1, read into b0

if b0=<dark_level then dark ' condition if dark

if b0>=light_level then light ' condition if light

Attachments

-

29.7 KB Views: 130

Last edited: