SilentScreamer

Senior Member

Hi all,

I've got a few questions relating to two PICAXE projects I currently have.

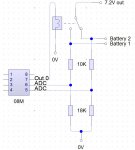

The first is monitoring a 7.2V battery (six 1.2V cells) on an electric remote control car and when it drops below a specific voltage (as yet to be decided) it will switch one relay off and turn the another on (to swap from one battery to another).

I thought about using an 08M and running the 7.2V battery through a voltage regulator. For the time that there is no battery (the competition rules state only one battery can be used else I would use them in parallel) I plan to use a capacitor to keep the power to the 08M. For monitoring the battery (only one needs to be monitored) I thought about using the ADC and then connecting 2 output pins

So my questions:

1) Does this sound like the best method of doing it or is there a better way?

2) What value capacitor would be suitable? I've found cheap ones that are 22000uF at rapid would this be too large or small? (I have very little knowlage of capacitors other that using them to fade LEDs as they turn off on breadboards)

3) Should I use a voltage reference on another ADC pin? Or have I misunderstood how to use voltage references?

4) Would this relay require a transistor or could I run it directly (I cant find a datasheet for it but I think it will use about 0.1A? (P/V=I therefore 0.51/5=0.102Amp)?

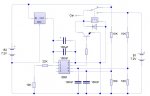

The other project is to make a clock with multiple chips (I currently plan the real time clock chip that technology supplies stock, a main 28X1 and also 2 additional PICAXEs to run twelve 7 segment displays). I want to do this project so I can simply learn more about I2C and getting PICAXEs to work together via serial.

So my questions:

5) To run the 7 segment displays I was going to use 28X1s to multiplex them (6 displays per X1, with 8 outputs used connected to each displays sections then one output directly connected to the cathode of each display, when I make the pin low it will allow current to flow into it and make a circuit). Would this work? Or is there a better way?

6) Is there a cheaper chip that would work (28X maybe?) for running six displays without running out of memory? Or should I just write the code then buy the chips? Or would it even be possible to use an 28/40X2 to run all 12 displays from one chip? I don't understand the X2's labelling in the manuals.

Thanks in advance for any help given

I've got a few questions relating to two PICAXE projects I currently have.

The first is monitoring a 7.2V battery (six 1.2V cells) on an electric remote control car and when it drops below a specific voltage (as yet to be decided) it will switch one relay off and turn the another on (to swap from one battery to another).

I thought about using an 08M and running the 7.2V battery through a voltage regulator. For the time that there is no battery (the competition rules state only one battery can be used else I would use them in parallel) I plan to use a capacitor to keep the power to the 08M. For monitoring the battery (only one needs to be monitored) I thought about using the ADC and then connecting 2 output pins

So my questions:

1) Does this sound like the best method of doing it or is there a better way?

2) What value capacitor would be suitable? I've found cheap ones that are 22000uF at rapid would this be too large or small? (I have very little knowlage of capacitors other that using them to fade LEDs as they turn off on breadboards)

3) Should I use a voltage reference on another ADC pin? Or have I misunderstood how to use voltage references?

4) Would this relay require a transistor or could I run it directly (I cant find a datasheet for it but I think it will use about 0.1A? (P/V=I therefore 0.51/5=0.102Amp)?

The other project is to make a clock with multiple chips (I currently plan the real time clock chip that technology supplies stock, a main 28X1 and also 2 additional PICAXEs to run twelve 7 segment displays). I want to do this project so I can simply learn more about I2C and getting PICAXEs to work together via serial.

So my questions:

5) To run the 7 segment displays I was going to use 28X1s to multiplex them (6 displays per X1, with 8 outputs used connected to each displays sections then one output directly connected to the cathode of each display, when I make the pin low it will allow current to flow into it and make a circuit). Would this work? Or is there a better way?

6) Is there a cheaper chip that would work (28X maybe?) for running six displays without running out of memory? Or should I just write the code then buy the chips? Or would it even be possible to use an 28/40X2 to run all 12 displays from one chip? I don't understand the X2's labelling in the manuals.

Thanks in advance for any help given

Last edited: