I am trying to control a motor (forward and reverse) using an L293D but its going too fast for my application (knitting machine.... yes, i said knitting).

Im using the 14m so there is only one PWM pin I can use.

Im still trying to get my head around HPWM and I came across this post...

http://letsmakerobots.com/node/2525

Is this possible? note that hes using output 1 and input 1, two different pins (confused me at first)

Im using the 14m so there is only one PWM pin I can use.

Im still trying to get my head around HPWM and I came across this post...

http://letsmakerobots.com/node/2525

Code:

The picaxe manual refers to the " hpwm motor driver datasheet" but the only reference I found was

on the picaxe forum archive where someone said the datasheet was being written. That was one

year ago. I gave up on HPWM and stuck with pwmout

You can use speed control in two directions with the pwmout command. Remember that 75% in

terms of pwm means the pwm pin is low 25% of the cycle and highthe other 75%

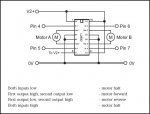

I connected output pin 1 and PWM1 (=input pin 1) to the motor driver for the motor A.

To move forward at 75% speed. make output 1 low and use pwm 1 with 75% of the cycle high.

To reverse at 75% speed. make output 1 high and use pwm 1 with 25% of the cycle high.

That way you only need 1 PWM signal per motorfor bi-directional speed control