PWM Motor Control, MOSFET getting VERY hot? - SOLVED!!!

Hi all, it's been a while since I've posted, but I hope someone can shed a little light on my latest project.

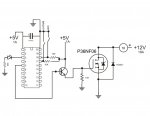

This is a simple project using a 20X2's PWM function on C.5 to manage the speed of a fairly high powered blower motor. The motor is rated at 12V 6A max.

The code is very simple. the PWM duty varied by two switches, the period is set at 250 for a PWM cycle of 4Khz, which I thought would be fine.

I have a realable 5v signal at the chip, and have added a large 4700uf Cap to ensure stability.

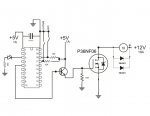

I am using a P36NF06 MOSFET by STmicro as the fan control, switching it with a simple 2N222A npn signal transistor, fired by pin5(pwm) from the 20x2.

When I use the setup to just test (using an LED and resistor as the load) all is well. When I use the motor, the MOSFET seems to be fine at either full power or no power, but the moment that a PWM signal is used to vary the motor speed, the MOSFET gets quite hot - so hot you can't touch it. This MOSFET is rated at 60V, 30A, with a gate threshold of between 2 and 4 volts, so it should be sufficient. Can anyone give me an idea as to what I'm doing wrong or what is missing in the schematic below? (The LED shown just flashes each cycle to let me know the picaxe is running)

Many thanks!

Here's the code:

Hi all, it's been a while since I've posted, but I hope someone can shed a little light on my latest project.

This is a simple project using a 20X2's PWM function on C.5 to manage the speed of a fairly high powered blower motor. The motor is rated at 12V 6A max.

The code is very simple. the PWM duty varied by two switches, the period is set at 250 for a PWM cycle of 4Khz, which I thought would be fine.

I have a realable 5v signal at the chip, and have added a large 4700uf Cap to ensure stability.

I am using a P36NF06 MOSFET by STmicro as the fan control, switching it with a simple 2N222A npn signal transistor, fired by pin5(pwm) from the 20x2.

When I use the setup to just test (using an LED and resistor as the load) all is well. When I use the motor, the MOSFET seems to be fine at either full power or no power, but the moment that a PWM signal is used to vary the motor speed, the MOSFET gets quite hot - so hot you can't touch it. This MOSFET is rated at 60V, 30A, with a gate threshold of between 2 and 4 volts, so it should be sufficient. Can anyone give me an idea as to what I'm doing wrong or what is missing in the schematic below? (The LED shown just flashes each cycle to let me know the picaxe is running)

Many thanks!

Here's the code:

Code:

Symbol Duty = W0

Duty = 400 ' start with medium duty

PWMOut C.5, 249, Duty

TOP:

GoSub Flash ' flash the LED on Out0

SerTxD (#Duty, 13, 10) ' used for debugging student programs

If PinB.0 = 0 and PinB.1 = 0 Then StopPWM ' if both pushbuttons depressed

If PinB.0 = 0 and PinB.1 = 1 Then Slower ' if one depressed

If PinB.0 = 1 and PinB.1 = 0 Then Faster ' if other depressed

' no change if neither depressed.

GoTo TOP ' continually loop

StopPWM:

PWMOut C.5, 0, Duty ' zero the period

GoTo TOP

Slower:

If Duty < 20 Then Top ' minimum floor

Duty = Duty - 15 ' decrease duty

PWMOut C.5, 250, Duty

Pause 100

GoTo TOP

Faster:

If Duty > 984 Then Top

Duty = Duty + 15 ' increase duty

PWMOut C.5, 250, Duty

Pause 100

GoTo TOP

Flash: ' flash LED on Out0

High C.7

Pause 100

Low C.7

Pause 100

Return

Last edited: