pwm, high/low or pulsout

- Thread starter xfred

- Start date

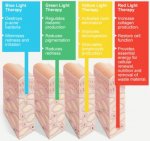

OK, here goes... it is well know and lots of documentation on the net (light therapy); that LED light of specific frequencys can be used to shorten or change healing time and healing of specific types of skin disorders. I have been researching this for a couple of years and have done experiments with timers and descreet circuits. now i'm ready to build a small hand held microprocessor controlled device. I have choosen the picaxe. it includes specific pulse frequecys between 1-100hz, with four led colors each timed for duration. each led is timed specifically to do it's work in healing. I include a small pic to give you an idea...

So, i need to control led's frequency 1-100hz, signal amplitude or ramp up/down, duration on/off completion time.

any help is greatly apprecaited. this is my first picaxe project...Thank you!

So, i need to control led's frequency 1-100hz, signal amplitude or ramp up/down, duration on/off completion time.

any help is greatly apprecaited. this is my first picaxe project...Thank you!

You seem to have added a requirement there, for amplitude. Can you expand on that a bit?So, i need to control led's frequency 1-100hz, signal amplitude or ramp up/down, duration on/off completion time.

Say you have your LED pulsing at 50Hz, do you want the pulses to vary by on/off time ratio to serve as amplitude control?

Or are you looking for even 50:50 on/off time (or some other fixed ratio) but the brightness of the LED to be variable for the duration of the on-pulse?

Hi,

Normally, PWM would be used to control the brightness of the light source, then updating the PWM values to switch/ramp the light levels using software loop delays (or just HIGH / LOW if the brightness does not need to be changed). For "completion" measurements, the "time" variable (seconds) is often the most useful.

I'm surprised you're not using/considering UV and/or IR light sources as well?

Cheers, Alan.

IMHO it would be better to think in terms of active periods (times) rather than frequency. For example 10Hz = 100 ms, etc. Then the range is 10 ms to 1000 ms, but you also need to specify the duty cycle (i.e. the ratio of ON to OFF times).i need to control led's frequency 1-100hz, signal amplitude or ramp up/down, duration on/off completion time.

Normally, PWM would be used to control the brightness of the light source, then updating the PWM values to switch/ramp the light levels using software loop delays (or just HIGH / LOW if the brightness does not need to be changed). For "completion" measurements, the "time" variable (seconds) is often the most useful.

I'm surprised you're not using/considering UV and/or IR light sources as well?

Cheers, Alan.

Alan,

agreed! i used it loosly here, I have a chart that helps me do the conversions... duty cycle is <=40%.

I have a full range of 3w led's that i have been playing with (ebay), UV (365-410nm) -i use for fast sterilization of wounds, 660nm-740nm and 850nm-940 for rapid healing.

agreed! i used it loosly here, I have a chart that helps me do the conversions... duty cycle is <=40%.

I have a full range of 3w led's that i have been playing with (ebay), UV (365-410nm) -i use for fast sterilization of wounds, 660nm-740nm and 850nm-940 for rapid healing.

I have found that pulsing the leds, leads to faster healing at specific frequency’s, reduces pain more rapidly and heals more rapidly. This has to do with skin reflex response (absorption spectrum) . When skin receives a light pulse it reacts like a rubber band to absorb the energy and then releases chemicals that begin the healing process (photoreceptor like ATP). As that skin response takes effect applying more light really does nothing (due to an opaque type attribute within skin, after initial pulse) , so there is a relax interval (off period) during which healing can take effect. Since skin reacts very slowly (being biological), things tend to go slow, therefore pulsing is in the range of 1-100hz. Above this is experimental with mixed results.

Modes: steady vs pulsed

Steady Led light activates the photoreceptors like ATP to begin healing, however steady light does not cause a relaxation period for the skin to relax the muscles and continue produce more chemicals to produce rapid healing. the more chemicals that can be released by the photo receptores and cause the muscles to contract and loosen, the faster the healing times.

one of the more interesting side effects of using led's like this is what type of chemicals are produced by the photo receptors, NO3... nitrogen-oxygen which attacks free radicals (contamination in the wound etc...) NO3 relaxes the muscles to come together and begin healing.

Here are some pictures that might help.

Modes: steady vs pulsed

Steady Led light activates the photoreceptors like ATP to begin healing, however steady light does not cause a relaxation period for the skin to relax the muscles and continue produce more chemicals to produce rapid healing. the more chemicals that can be released by the photo receptores and cause the muscles to contract and loosen, the faster the healing times.

one of the more interesting side effects of using led's like this is what type of chemicals are produced by the photo receptors, NO3... nitrogen-oxygen which attacks free radicals (contamination in the wound etc...) NO3 relaxes the muscles to come together and begin healing.

Here are some pictures that might help.

Last edited:

hippy

Ex-Staff (retired)

Pulsing the LEDs at various rates (freqency) with various duty cycles should be reasonably easily achievable. The question is, whether the intensity of the LEDs also need to be controllable when pulsed on ?

rossko57's query, post #9, also relates to how that would be done.

Also, would only one LED colour be activated at any time or could multiple LEDs be active together ?

rossko57's query, post #9, also relates to how that would be done.

Also, would only one LED colour be activated at any time or could multiple LEDs be active together ?

Pulsing the LEDs at various rates (freqency) with various duty cycles should be reasonably easily achievable. The question is, whether the intensity of the LEDs also need to be controllable when pulsed on ?

rossko57's query, post #9, also relates to how that would be done.

Also, would only one LED colour be activated at any time or could multiple LEDs be active together ?

Yes, muliple led's are active together during the healing process. at specific times; sterilize, heal, reduce pain, heal, reduce scar, heal, reduce pain etc...

premelec

Senior Member

I'm not quite following what you need but mention that I've done Constant Current LED drive using digitally controlled [from PICAXE] DACs which generate a ref voltage to an OPamp to a MOSFET gate with a current sense resistor in it's drain path. The CC stays stable until a new DAC value is issued, and can be modulated on and off with a frequency signal. This implies a bit of external completxity but with the power LEDs they are going to need externals...

progress

i intend to drive the 3w leds with mosfets also, no problems there. temperature is however an issue, i'm thinking of using temp sensors to ADC pins on the heat sinks. (possibly micro fans)I also was thinking of plans for a constant current led drive, i like what your saying... there is overlapping in led colors, but only two or three at a time. this is mostly a software timing issue. after reading what everyone is saying, i think PWM and on/off as mentioned is the way to go, are their any timing charts for the picaxe20m2 ???

thanks to everyone for the assistance!

Sorry for delay, been solving lcd display code problems all day and night, silly how just a simple syntax ' ` " can get ya, well that and...I'm not quite following what you need but mention that I've done Constant Current LED drive using digitally controlled [from PICAXE] DACs which generate a ref voltage to an OPamp to a MOSFET gate with a current sense resistor in it's drain path. The CC stays stable until a new DAC value is issued, and can be modulated on and off with a frequency signal. This implies a bit of external completxity but with the power LEDs they are going to need externals...

i intend to drive the 3w leds with mosfets also, no problems there. temperature is however an issue, i'm thinking of using temp sensors to ADC pins on the heat sinks. (possibly micro fans)I also was thinking of plans for a constant current led drive, i like what your saying... there is overlapping in led colors, but only two or three at a time. this is mostly a software timing issue. after reading what everyone is saying, i think PWM and on/off as mentioned is the way to go, are their any timing charts for the picaxe20m2 ???

thanks to everyone for the assistance!