I've been toying with ideas since Mad Professor brought it up last February. I have a technique that works like a champ. The idea started as a "choke input filter." These were the only way to get filtered DC years ago - there were no electrolytic caps or they were large and dangerous, so you used paper/foil caps in mineral oil and large inductors to filter DC through multistage pi networks.

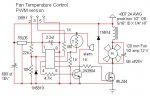

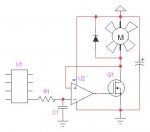

Works like a champ for taking the PWM from an axe - to a mosfet to control brushless fans without all the chirping and odd impeller behavior. Only anomaly was a hell of a voltage spike across the source drain junction of the mosfet - no problemo a diode around the inductors (fan and choke) returns the spike to the power supply and improves efficiency. Voila! the same circuit as you see in "buck type switching converters" just minus the feedback loop.

I'll put a write up of the thing in the finished designs section when I get around to it. The pwm is running along at 7,000 HZ. Using a 1N914 is perfectly acceptable since the flyback pulse contains very little energy. My fan is a one half amp, twelve volt, 120 mm size case fan. No parts get warm while in operation and a heatsink isn't necessary. Only two caveats "debug" may interfere with operation so only use it to see what's happening, but don't expect it to work if you leave it in the code - AND the power supply must connect to the fan/inductor and mosfet source - the rest of the circuit should be laid out as the schematic suggests - letting the power pulses travel down the same wires/traces that feed the axe is asking for problems - especially on one of the solderless breadboards. Bypass the axe as shown.

The inductor specs? I had a number of ferrite and powdered iron cores laying around and just stuffed one with as much wire as it would hold and still look "right." Any kind of high permeability core or "hash" filter choke should work. 7,000 HZ is low frequency - out of the range of laminations but well within the range of powdered iron. I tried several I had laying around and they all worked. I'd guess there's 1,000 mhy inductance in the one I'm using.

68 uf across the fan is not critical at all, 50 -1000 worked fine.

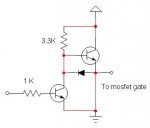

The 1K to the gate of the mosfet is superfluous - I had a darlington in there at one time and that was just a limiting resistor for the base drive. Darlington will work fine, but the efficiency is higher with a mosfet.

Works like a champ for taking the PWM from an axe - to a mosfet to control brushless fans without all the chirping and odd impeller behavior. Only anomaly was a hell of a voltage spike across the source drain junction of the mosfet - no problemo a diode around the inductors (fan and choke) returns the spike to the power supply and improves efficiency. Voila! the same circuit as you see in "buck type switching converters" just minus the feedback loop.

I'll put a write up of the thing in the finished designs section when I get around to it. The pwm is running along at 7,000 HZ. Using a 1N914 is perfectly acceptable since the flyback pulse contains very little energy. My fan is a one half amp, twelve volt, 120 mm size case fan. No parts get warm while in operation and a heatsink isn't necessary. Only two caveats "debug" may interfere with operation so only use it to see what's happening, but don't expect it to work if you leave it in the code - AND the power supply must connect to the fan/inductor and mosfet source - the rest of the circuit should be laid out as the schematic suggests - letting the power pulses travel down the same wires/traces that feed the axe is asking for problems - especially on one of the solderless breadboards. Bypass the axe as shown.

The inductor specs? I had a number of ferrite and powdered iron cores laying around and just stuffed one with as much wire as it would hold and still look "right." Any kind of high permeability core or "hash" filter choke should work. 7,000 HZ is low frequency - out of the range of laminations but well within the range of powdered iron. I tried several I had laying around and they all worked. I'd guess there's 1,000 mhy inductance in the one I'm using.

68 uf across the fan is not critical at all, 50 -1000 worked fine.

The 1K to the gate of the mosfet is superfluous - I had a darlington in there at one time and that was just a limiting resistor for the base drive. Darlington will work fine, but the efficiency is higher with a mosfet.

Attachments

-

30.5 KB Views: 137