No real need to redo the test as i think you have answered the question ... it filckers... if your rpm was higher you would not see the flicker, so hence the reverse led test as one dont know how your tests are conducted.SAborn. No I didn't try the gnd way around with the LED. When connected the positive way straight from W connection it was flickering on and off at low revs I assume from that it was AC. But I will try it and let you know.

Working with a guess of 300 RPM low revs, and a 1:3 ratio of the pulleys (6" to 2") that would give a alternator speed of about 900 RPM, divided by 60 (sec) would give 15 Hz, and well within the optical range to see the Led flicker.

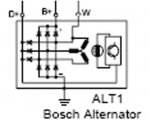

My guess its a single phase from the 3 phases that is connected to W terminal, it could be the star connection of the 3 phase, but would think its a diode gated connection to a single phase, and more than likely a DC square wave output. Then im just guessing here.