laserhawk64

Senior Member

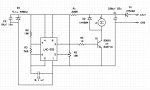

For a Picaxe-free project I'm working on, I need to control two motors, so that one is rotating opposite the other. I found a schematic on the Talking Electronics webpage (here, "Design 1" about 1/4 way down) that should work with some adaptation.

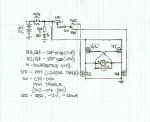

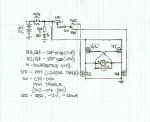

I'd like to use IRF510/IRF9510 transistors (or smaller, but they have to handle the stall current of about half an amp per motor IMO) and I want them to have a speed control. I've got a circuit diagram (attached) but I want to know three things...

(1) what value for the potentiometer (speed control)?

(2) will this work without any further changes? (if not, what does it need that it's missing?)

(3) is there a way to make this circuit even simpler, without losing functionality?

Motors here. Power is 4xAAs, so either 4.8v or 6v, depending on battery type. (Assume 6v disposables.)

FWIW, the idea is to build a simple motor-and-crank walking "robot" toy with handheld wired controller, as a kid-friendly set of instructions to (eventually) submit to Make: Magazine (obviously, credit will be given if it hits print). I'd like to think that they'd be interested in featuring something simple that a parent and child could build together in a weekend for about US$30 (at most) from a little bit of electronics and some flotsam. (To be completely kid-friendly, I want to keep soldering --and electronics-- to a minimum.)

I'd like to use IRF510/IRF9510 transistors (or smaller, but they have to handle the stall current of about half an amp per motor IMO) and I want them to have a speed control. I've got a circuit diagram (attached) but I want to know three things...

(1) what value for the potentiometer (speed control)?

(2) will this work without any further changes? (if not, what does it need that it's missing?)

(3) is there a way to make this circuit even simpler, without losing functionality?

Motors here. Power is 4xAAs, so either 4.8v or 6v, depending on battery type. (Assume 6v disposables.)

FWIW, the idea is to build a simple motor-and-crank walking "robot" toy with handheld wired controller, as a kid-friendly set of instructions to (eventually) submit to Make: Magazine (obviously, credit will be given if it hits print). I'd like to think that they'd be interested in featuring something simple that a parent and child could build together in a weekend for about US$30 (at most) from a little bit of electronics and some flotsam. (To be completely kid-friendly, I want to keep soldering --and electronics-- to a minimum.)