Opps

- Thread starter Jarubell

- Start date

premelec

Senior Member

Toothpicks

For decades I've used wooden toothpicks to chase solder bridges and move molten solder around. Once the wooden toothpick has a little flux on it and chars a bit it does wonders - and you can clip it sharper if need be and they are cheap! I use _flat_ rather than round picks as they seem more versatile... so toothpicaxe...

For decades I've used wooden toothpicks to chase solder bridges and move molten solder around. Once the wooden toothpick has a little flux on it and chars a bit it does wonders - and you can clip it sharper if need be and they are cheap! I use _flat_ rather than round picks as they seem more versatile... so toothpicaxe...

De-Soldering Iron

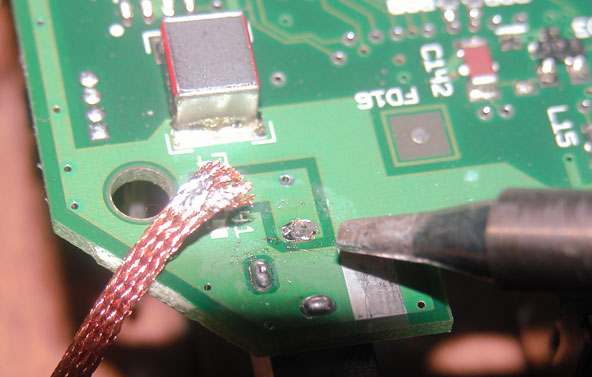

Next time you in your local electronics shop, keep an eye out for a de-soldering iron. Got mine for under $10 and it is very handy.Well, I was trying to solder a header on a AXE033 with little experience and just as I was getting the hang of it, I soldered across to the next pin. So, i'm looking for ideas ho to fix this?

Attachments

-

107.7 KB Views: 28

inglewoodpete

Senior Member

I usually use a good, clean, tinned soldering iron and gravity. Hold the board vertically and quickly melt the solder blob with the soldering iron. Then move the iron down and away from the board. Hey presto: a cleaned joint!

Yes, I agree. I tend to hold the board slightly "off vertical" with the copper side downwards. With the solder melted, tap the edge of the board gently on the bench to encourage the solder to drop off.I usually use a good, clean, tinned soldering iron and gravity. Hold the board vertically and quickly melt the solder blob with the soldering iron. Then move the iron down and away from the board. Hey presto: a cleaned joint!

As someone else has posted, for the longer term a solder sucker is well worth getting.

John.

The trouble with solder suckers & wick is that they're never handy when you need them, AND also that they'll now often visually obscure todays very small components, tracks & pads.

A skinflint's trick from yesteryear however can come to the rescue- this involves VERY fine multistranded wire fluxed with a smear of lemon juice. It's not only cheap but works absolute magic on the fiddliest blunders,and offers a lovely aroma at close quarters!

My 2 cents worth... Stan.

A skinflint's trick from yesteryear however can come to the rescue- this involves VERY fine multistranded wire fluxed with a smear of lemon juice. It's not only cheap but works absolute magic on the fiddliest blunders,and offers a lovely aroma at close quarters!

My 2 cents worth... Stan.

BeanieBots

Moderator

tI've used premelec's 'toothpick' method before but that's a new one on me Stan!

I've got to have to have a go at that. The smell of burning lemon juice sounds better than flux fumes However, my tool box always has a solder-sucker in it, but I don't think it's ever contained a lemon

However, my tool box always has a solder-sucker in it, but I don't think it's ever contained a lemon

I've got to have to have a go at that. The smell of burning lemon juice sounds better than flux fumes

hippy

Ex-Staff (retired)

One tip I've found for a stubborn bridge and a solder sucker is to add new solder to the bridge and then suck the whole lot up.

On vero-board, where you can end up with more solder than you'd like, I usually use a craft knife to cut / 'de-grout' between tracks to ensure there are no shorts. Sometimes there's a really stubborn short between tracks and there's little choice but to remove all or most solder, clean the divide and re-solder.

On vero-board, where you can end up with more solder than you'd like, I usually use a craft knife to cut / 'de-grout' between tracks to ensure there are no shorts. Sometimes there's a really stubborn short between tracks and there's little choice but to remove all or most solder, clean the divide and re-solder.

Thanks all for the replies and methods. I just checked the fridge and my lovely wife does have lemon juice in there! So tonight if I did not make it to the store I will try the RG6 cable with lemon juice.

But my big lesson of last night is to some how find a way to hold my project before I attempt to solder!

Thanks again!

But my big lesson of last night is to some how find a way to hold my project before I attempt to solder!

Thanks again!

For small boards, a "helping hands" tool like this one

http://www.harborfreight.com/helping-hands-319.html from Harbor Freight. (Isn't there a similar store in Canada? Has "Tire" in the name?)

Amazon also offers a similar tool

http://www.amazon.com/Helping-Hands-with-Magnifying-Glass/dp/B000RB38X8

as do the various electronics houses:

MPJA http://www.mpja.com/prodinfo.asp?number=1006+TL

Goldmine Electronics http://www.goldmine-elec-products.com/prodinfo.asp?number=G12810

For larger boards, I have an adjustable board holder that has a tilt/swivel head to turn the board to the right position for working on it. It's mounted on a piece of 2x4 (4x2 for NZ/AU) to provide enough weight to balance larger boards. It's more than 30 years old and I no longer remember the source (if I did remember, they might not be in business now). My tool is probably the grandfather of this one http://www.qsource.com/p-1987-jerry-rig-universal-work-positioner-wu-style-spring-loaded-pcb-vise-freestanding-base.aspx

John

http://www.harborfreight.com/helping-hands-319.html from Harbor Freight. (Isn't there a similar store in Canada? Has "Tire" in the name?)

Amazon also offers a similar tool

http://www.amazon.com/Helping-Hands-with-Magnifying-Glass/dp/B000RB38X8

as do the various electronics houses:

MPJA http://www.mpja.com/prodinfo.asp?number=1006+TL

Goldmine Electronics http://www.goldmine-elec-products.com/prodinfo.asp?number=G12810

For larger boards, I have an adjustable board holder that has a tilt/swivel head to turn the board to the right position for working on it. It's mounted on a piece of 2x4 (4x2 for NZ/AU) to provide enough weight to balance larger boards. It's more than 30 years old and I no longer remember the source (if I did remember, they might not be in business now). My tool is probably the grandfather of this one http://www.qsource.com/p-1987-jerry-rig-universal-work-positioner-wu-style-spring-loaded-pcb-vise-freestanding-base.aspx

John

Last edited: