Model Railroad turntable

To make a turntable stop at 10 indexed spots

Can this be done ?

Using

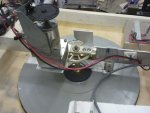

Gear motor controlled by L298 board with pwm input and high enables for forward and reverse.

Encoder wheel with 29 slots on ungeared shaft on rear of gear motor

There are approximately 12,600 pulses per full revolution of actual turntable on geared shaft.

(Found using picaxe count command)

Using 1 pushbutton per input per rail stop spot for a total of 10 positions

or

I also have a keypad 4X3 rows pdf here http://www.robotshop.com/productinfo.aspx?pc=RB-Spa-203&lang=en-US

An axe022 project board and some 28x1’s

An ch30 project board or ch35 with 18x in them

The mechanical side is done but can be changed

The electronics is done more or less using an ch30 project board without the second chip in it and direct wired to picaxe 18x outputs for pwm and highs and lows

My weak point is programing of course, I have got it to rotate both ways with pwm to l298 and figured out the count command enough to see it work.

But putting it all together is beyond me without at least a starting point in the picaxe basic.

So some help would be appreciated.

Thanks, Hugh

To make a turntable stop at 10 indexed spots

Can this be done ?

Using

Gear motor controlled by L298 board with pwm input and high enables for forward and reverse.

Encoder wheel with 29 slots on ungeared shaft on rear of gear motor

There are approximately 12,600 pulses per full revolution of actual turntable on geared shaft.

(Found using picaxe count command)

Using 1 pushbutton per input per rail stop spot for a total of 10 positions

or

I also have a keypad 4X3 rows pdf here http://www.robotshop.com/productinfo.aspx?pc=RB-Spa-203&lang=en-US

An axe022 project board and some 28x1’s

An ch30 project board or ch35 with 18x in them

The mechanical side is done but can be changed

The electronics is done more or less using an ch30 project board without the second chip in it and direct wired to picaxe 18x outputs for pwm and highs and lows

My weak point is programing of course, I have got it to rotate both ways with pwm to l298 and figured out the count command enough to see it work.

But putting it all together is beyond me without at least a starting point in the picaxe basic.

So some help would be appreciated.

Thanks, Hugh