Hi All,

I have been playing around with PICAXE for a few years but only for fun. Now I have a more serious project to complete but not sure where to start with the code.

Firstly, I am not an electronic expert and play around for pleasure and learning. I know a bit more than a beginner but still have a long way to go. I am ok with most electronic components and know how most work and operate but only to a basic level.

Now on to the project. I currently own an aircraft. Earlier this year I installed an electronic flight information system (EFIS) in to it. For anyone that doesn't know, the EFIS displays a variety of flight parameters to me such as speed, height, oil temperature and pressure and navigation information. Another item it will display is engine RPM. Unfortunately it will not display the RPM on my engine due to the following reason.

The RPM is detected by a Hall effect sensor which counts the teeth on the flywheel. Every time a flywheel tooth passes the sensor, the sensor creates a pulse. The flywheel has 60 teeth so 60 pulses equals 1 revolution of the engine. The EFIS cannot cope with that number of pulses with about 6 pulses per revolution being the maximum. The EFIS has a configuration item in its menu for the number of pulses per revolution.

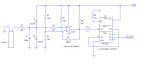

I need to design a circuit that will read the pulses from the Hall effect sensor and then send about 4 pulses per revolution out of an output pin to the EFIS. This basically means that when 15 pulses have been read from the Hall effect sensor, it sends a pulse to the EFIS and then another output pulse after the next 15 pulses read from the sensor and so on.

This is where I am lost. I am fine creating the circuit to do this but have no idea what code to write to do it. Bearing in mind that the engine has the potential to run at 3300 RPM, there cannot be much delay in sending output pulses considering that the Hall effect sensor could be creating 3300 pulses per second maximum.

I would really appreciate if someone could advise me on the PICAXE code required to do this. I had a look in the manual at the PULSIN and PULSOUT commands but they really didn't make much sense to me as I have never had to deal with pulses before.

Many thanks in advance.

Steve

I have been playing around with PICAXE for a few years but only for fun. Now I have a more serious project to complete but not sure where to start with the code.

Firstly, I am not an electronic expert and play around for pleasure and learning. I know a bit more than a beginner but still have a long way to go. I am ok with most electronic components and know how most work and operate but only to a basic level.

Now on to the project. I currently own an aircraft. Earlier this year I installed an electronic flight information system (EFIS) in to it. For anyone that doesn't know, the EFIS displays a variety of flight parameters to me such as speed, height, oil temperature and pressure and navigation information. Another item it will display is engine RPM. Unfortunately it will not display the RPM on my engine due to the following reason.

The RPM is detected by a Hall effect sensor which counts the teeth on the flywheel. Every time a flywheel tooth passes the sensor, the sensor creates a pulse. The flywheel has 60 teeth so 60 pulses equals 1 revolution of the engine. The EFIS cannot cope with that number of pulses with about 6 pulses per revolution being the maximum. The EFIS has a configuration item in its menu for the number of pulses per revolution.

I need to design a circuit that will read the pulses from the Hall effect sensor and then send about 4 pulses per revolution out of an output pin to the EFIS. This basically means that when 15 pulses have been read from the Hall effect sensor, it sends a pulse to the EFIS and then another output pulse after the next 15 pulses read from the sensor and so on.

This is where I am lost. I am fine creating the circuit to do this but have no idea what code to write to do it. Bearing in mind that the engine has the potential to run at 3300 RPM, there cannot be much delay in sending output pulses considering that the Hall effect sensor could be creating 3300 pulses per second maximum.

I would really appreciate if someone could advise me on the PICAXE code required to do this. I had a look in the manual at the PULSIN and PULSOUT commands but they really didn't make much sense to me as I have never had to deal with pulses before.

Many thanks in advance.

Steve