nitrous2000

Member

Hi guys,

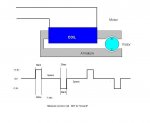

I'm trying to generate an alternating current signal to drive a quartz clock stepper motor. There is only one coil. I believe the drive relies on alternating the poles by cycling the drive voltage. These are not expensive dual coil movements.

Space is at a premium. I would like to know how to do it with a PIC (since I might be looking at sensing a position of the shaft, at some point down the road) but have been told it can be done with a single 555 timer with a capacitor or a pair of 555's.

I've been having trouble searching Google for this since all "DC-AC inverter" searches lead me to power inverters for generating mains voltage from a 12v DC power source. What should I be searching for (in terms of schematics/circuit designs on the hobby electronics sites)

Thanks

Nitrous

I'm trying to generate an alternating current signal to drive a quartz clock stepper motor. There is only one coil. I believe the drive relies on alternating the poles by cycling the drive voltage. These are not expensive dual coil movements.

Space is at a premium. I would like to know how to do it with a PIC (since I might be looking at sensing a position of the shaft, at some point down the road) but have been told it can be done with a single 555 timer with a capacitor or a pair of 555's.

I've been having trouble searching Google for this since all "DC-AC inverter" searches lead me to power inverters for generating mains voltage from a 12v DC power source. What should I be searching for (in terms of schematics/circuit designs on the hobby electronics sites)

Thanks

Nitrous