How many ways are there to reset a picaxe?

I have a picaxe system that works, as designed, perfectly but keeps resetting itself randomly. It does this at a rate of once every 48 hours to about once every 2 hours.

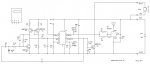

I have previously built over 100 of these systems without this problem. The last batch consisted of a new artwork, new wireless transmitter module and used a 08m2 picaxe instead of the 08m I had used previously. It is powered by 3 AAA cells, decoupled by a surface mount 0.1uF ceramic capacitor very close to the 08m2 Vcc and 0v pins and with a 33uF bulk capacitor. The new wireless transmitter module was disconnected early in the investigation. Pin 2 (serin) was initially connected to 0v via 10k but the resistor has been shorted out.

20 of the units were built and the power to them were all wired in parallel to a reliable, stabilized power supply to eliminate intermittents in the supply source.

The software works by going through an initialization section which beeps at the beginning and beeps for a second time at the end of the initialization section then goes to the main: portion. In main: it calls a number of other sub routines and cycles round these including a sleep1 command. It is not possible for the initialization section to be restarted. The disablebod and enablebod have been removed and disablebod added at the end of the initialization section.

The circuit and software are essentially the same as the first 100 units with only minor changes.

I added a little routine to the initialization section which counts and stores to EEPROM the number of starts the unit has made and using debug transmits this number whenever the chip is repowered.

I have determined the worst and the best boards then swapped the chips to see if the problem is the board or the chips. No consistent result occurred; the fault rate was still random.

How many ways are there to reset a picaxe?

I have a picaxe system that works, as designed, perfectly but keeps resetting itself randomly. It does this at a rate of once every 48 hours to about once every 2 hours.

I have previously built over 100 of these systems without this problem. The last batch consisted of a new artwork, new wireless transmitter module and used a 08m2 picaxe instead of the 08m I had used previously. It is powered by 3 AAA cells, decoupled by a surface mount 0.1uF ceramic capacitor very close to the 08m2 Vcc and 0v pins and with a 33uF bulk capacitor. The new wireless transmitter module was disconnected early in the investigation. Pin 2 (serin) was initially connected to 0v via 10k but the resistor has been shorted out.

20 of the units were built and the power to them were all wired in parallel to a reliable, stabilized power supply to eliminate intermittents in the supply source.

The software works by going through an initialization section which beeps at the beginning and beeps for a second time at the end of the initialization section then goes to the main: portion. In main: it calls a number of other sub routines and cycles round these including a sleep1 command. It is not possible for the initialization section to be restarted. The disablebod and enablebod have been removed and disablebod added at the end of the initialization section.

The circuit and software are essentially the same as the first 100 units with only minor changes.

I added a little routine to the initialization section which counts and stores to EEPROM the number of starts the unit has made and using debug transmits this number whenever the chip is repowered.

I have determined the worst and the best boards then swapped the chips to see if the problem is the board or the chips. No consistent result occurred; the fault rate was still random.

How many ways are there to reset a picaxe?