fritz42_male

Senior Member

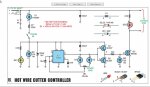

Hey guys, I fancy building myself a hot wire cutter for polystyrene. December Silicon Chip magazine has an article on this but using a 555 timer for PWM and an IRF540. I fancy doing this with an 08M and IRL540 - got the bits already. Anybody see any issues?

What's the simplest way of powering an 08M from 12V regulated supply? - I was thinking a 5V Zener with current limiting resistor as per the article.

What's the simplest way of powering an 08M from 12V regulated supply? - I was thinking a 5V Zener with current limiting resistor as per the article.