Here's a fairly complete analysis for you. You may want to read some of this twice. I can't describe things very clearly in text format. I'm more of a talker. I'd suggest you glance at a copy of the schematic as you read this. It will make more sense:

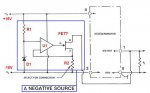

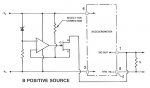

As Premelec indicated, the whole purpose of the circuit is to use an op-amp and driver FET to maintain a fixed current flowing through R2, (and to select that value of current by selecting the correct R2 value.) In this case, that's -1.3 mA. This is accomplished by a common bi-polar (+/- supply) single op-amp (such as a uA741, LM301, LM321, LF351, TL071) whose output will, in this circuit operating off the negative power supply rail, attempt to cause its inverting (-) input voltage to be driven to match the Zener reference voltage on its noninverting input (+).

It will do this by driving the FET (any small-signal common N channel FET will do, BS170, 2N7000, etc) so that it maintains a given voltage (that of the Zener,) across R2, which will thus have a fixed current flowing through it. The voltage drop across R2 will be forced by the op-amp and FET combination to be identical to the Zener reference voltage.

As far as component values are concerned, we must start with the Zener, as the voltage of the Zener you select will determine the other component values. Though others will certainly work, I'd suggest something like a common 1W 5.1V Zener (example: 1N4733A) for the voltage reference. Chose commonly available parts whenever you can in order to save money and avoid problems later on. If you don't already know what's commonly used, do a web search for something like "Zener diode," and see what pops up on the first page or two of results. (Or ask someone here.)

Then pick a value of R1 that will provide sufficient current to drive the Zener into its linear regulating range. (Check the Zener's data sheet.) Something like 10 mA should work (but check it, as that's a generalization for this example.) The lower the current that flows in the circuit the better as far as power conservation is concerned. However, the Zener must be driven hard enough to be certain it will stay within its linear regulation range during any load fluctuation. In this circuit, the choice of an appropriate resistor is made easy, as the op-amp input is the only load, and that is both negligible and doesn't fluctuate.

With a +/- power supply voltage differential of 30 volts, and a Zener diode drop of ~5 Volts, you have to drop 25V across R1. Ohm's Law then calculates an R1 value of 2.5K Ohm if you want 10 mA to flow through it and the Zener. (The op-amp will have negligible current flowing into its inputs.) Any value close to the 2.5K value will be fine. The Zener diodes are reasonably tolerant of input current range. Again, select the actual resistor value used based on the data sheet for the Zener you use.

With a 10 mA current flowing through a Zener diode that drops 5.1 volts, there will be a power dissipation of 50 mW (Ohm's Law for power; P=IE.) This is well within the diode's power spec of 1W dissipation.

Next comes the key component selection, that for which the circuit was designed.

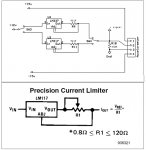

For resistor R2 you must pick a value that will cause a 5.1 Volt drop when 1.3 mA of current flows through it. As we already know, the circuit is designed to force a 5.1V drop across R2. Therefore we must select it's resistance value to ensure that 1.3 mA is flowing through it when 5.1V is dropped across it. Ohm's Law again finds the correct resistor value. R=E/I. Resistance equals voltage divided by current. You can do the math.

As resistors are fixed values, in this case, if a precise -1.3 mA current flow is desired, a trimmer potentiometer may be necessary to get the correct resistance value. The bias nulling current will be off by the value selected for this resistor as well as the error caused by the inaccuracy of the actual Zener voltage. Also, any difference between the -1.3 mA offset specified as being required and the actual offset required for your particular accelerometer chip.

That component selection is clearly based on your choice of degree of bias current nulling precision for your application and (as Premelec mentioned,) the code you use. Bias current nulling precision may not be an issue in your application, as the schematic shows a fixed resistor for R2.

Note that for anything resembling violent accelerations, use of a trim pot is probably not a very good idea. If both precision and mechanical reliability are important, then consider using 2 resistors (in parallel or series) for the value of R2 in order to get a precise current flow, i.e. use a resistor value just under that desired, and another with a very small value (series,) or one with a value just over that desired and one with a very high value (parallel,) in order to get very close to the required total resistance value.

In addition to the actual resistance values, we must also select resistors based on their power handling (wattage) capacity. Use Ohm's Law for power (P=IE; power in watts equals current in amps times voltage dropped across the device,) to calculate the power dissipation of each resistor value selected for this circuit to ensure you use resistors rated for sufficient wattage dissipation. At this supply voltage, Zener ref resistor R1 may require careful attention to proper power sizing, depending on the actual drive current selected.

Assuming the circuit shown is appropriate for the accelerometer used, you will then have a negative 1.3 mA flowing through the R2 circuit to act as your bias offset nulling current.