I got a bit excited and bought an accelerometer IC from RS without really checking what I was getting.

When it arrived, it turned out to be almost microscopic! Here is the link

MMA7361LCT

So not exactly suitable for a breadboard.

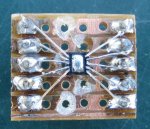

I was thinking maybe it would be possible to create my own little breakout board with the chip in the middle...and larger pins at the sides which I can connect to my picaxe easily. I googled surface mounting, and using flux and reheating with a hot air gun, it looks like it might be possible. I might as well have a shot, because the alternative is never use it anyway.

However, the videos and tutorials I have seen on the subject all seem to start with a PCB which already has a 'footprint' for the IC. And the pads all seem to be isolated. I can't see how they are connected to the rest of the circuit.

So I have two problems I am hoping people can help me with:

1. How is this kind of 'footprint' done..and how does it connect to the rest of the circuit. Can I draw one myself that tiny with a PCB and pen, then etch it all away. Or does it need to be a multilayer PCB or something?

2. I can't afford to buy any circuit making software. I've tried a number of free ones, but none of them seem to handle components of this size. Is there any free PCB software out there which you can recommend for making tiny circuits like this?

Thanks for any help you can offer

When it arrived, it turned out to be almost microscopic! Here is the link

MMA7361LCT

So not exactly suitable for a breadboard.

I was thinking maybe it would be possible to create my own little breakout board with the chip in the middle...and larger pins at the sides which I can connect to my picaxe easily. I googled surface mounting, and using flux and reheating with a hot air gun, it looks like it might be possible. I might as well have a shot, because the alternative is never use it anyway.

However, the videos and tutorials I have seen on the subject all seem to start with a PCB which already has a 'footprint' for the IC. And the pads all seem to be isolated. I can't see how they are connected to the rest of the circuit.

So I have two problems I am hoping people can help me with:

1. How is this kind of 'footprint' done..and how does it connect to the rest of the circuit. Can I draw one myself that tiny with a PCB and pen, then etch it all away. Or does it need to be a multilayer PCB or something?

2. I can't afford to buy any circuit making software. I've tried a number of free ones, but none of them seem to handle components of this size. Is there any free PCB software out there which you can recommend for making tiny circuits like this?

Thanks for any help you can offer