Hello all,

I am working on a project that I believe is similar to this, but looking for a bit more information to get me started.

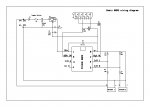

Making a psu unit, it is a simple design-12v Supply, 24V supply- these are both separate regulated psu's, and a desktop psu that I want to make as a variable supply (0-24V).

The fixed psu's are just going to be used as a convenience, if I need.

I have 2 7 segment LEDs that I want to display the selected voltage. The way I imagine this circuit would have a 3 way switch (12v and 24V) and the last connecting to a pot to select voltage (0-24V dc.)

I have read a bit on the readadc command, but cannot find alot of info on it, so I dont know if I am heading in the right direction.

What are the capabilities of this "command" or input? If I send 24v to the chip, I would imagine it would fry it, correct?

I also imagine that I will need to somehow use one 08m2 chip to drive both segment displays, which I believe this can do? Somehow divide the digit display. example 12V input- (1) output on A display (2) output to B display. ??

I apologize if this is in another thread already.

This is my first real project besides turning on and off an led, so dont make it too easy for me

Gotta learn the hard way

If you have any ideas as were I can reference to get me started on this path, any help would be appreciated!

Thanks