donrecardo

Senior Member

Hi

I am sorry that this isnt about a Picaxe problem but I know from the time I have been

on this forum that there are many clever people on here and maybe one of them

might be able to assist me

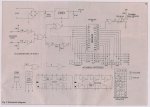

I have a CD4059 divide by N counter chip

I have the data sheet and have studied it for hours but I still cant make top nor tail

of it with its Ka, Kb Kc and jam inputs

I want to use three BCD thumb wheel switches ( Hundreds , Tens and Units)

to enable me to divide an input frequency by any integer in the range of 3 to 150

which I would set up on the 3 switches

As I said , I have really tried but I just cant follow the reasoning in the data sheet

I think its probably an age thing now that I am an old bugger

Can someone please give me a diagram of how I should connect it up before I pull

out the little hair I have left

Fingers Crossed

Don

I am sorry that this isnt about a Picaxe problem but I know from the time I have been

on this forum that there are many clever people on here and maybe one of them

might be able to assist me

I have a CD4059 divide by N counter chip

I have the data sheet and have studied it for hours but I still cant make top nor tail

of it with its Ka, Kb Kc and jam inputs

I want to use three BCD thumb wheel switches ( Hundreds , Tens and Units)

to enable me to divide an input frequency by any integer in the range of 3 to 150

which I would set up on the 3 switches

As I said , I have really tried but I just cant follow the reasoning in the data sheet

I think its probably an age thing now that I am an old bugger

Can someone please give me a diagram of how I should connect it up before I pull

out the little hair I have left

Fingers Crossed

Don