While I decide what's wrong with my HP03 pressure circuit, I decided to try an MPX4115A instead.

It seems to be working but, as the volatge swing is so small at the pressures we're interested in, I added an amplifier using a AD623 but I'm not having much luck with this either!

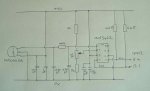

I'd hoped the attached circuit would give me a decent voltage swing between 0 and 4.9(ish) volts for an input differential of between 3.8 and 4.3 volts.

I've adjusted the 10-turrn pot to put 3.8 volts on pin 2 and the voltage from the MPX4115A is 4.09 volts. With the AD263 pin 5 grounded, it doesn't matter what gain resistor I use, I just get 0.09v at the output. With pin 5 open I just get virtually the supply volatge (5v) out.

Am I leading myself up the garden path here and the circuit will never do what I think it should or does the AD263 seem duff?

Thanks,

John.

It seems to be working but, as the volatge swing is so small at the pressures we're interested in, I added an amplifier using a AD623 but I'm not having much luck with this either!

I'd hoped the attached circuit would give me a decent voltage swing between 0 and 4.9(ish) volts for an input differential of between 3.8 and 4.3 volts.

I've adjusted the 10-turrn pot to put 3.8 volts on pin 2 and the voltage from the MPX4115A is 4.09 volts. With the AD263 pin 5 grounded, it doesn't matter what gain resistor I use, I just get 0.09v at the output. With pin 5 open I just get virtually the supply volatge (5v) out.

Am I leading myself up the garden path here and the circuit will never do what I think it should or does the AD263 seem duff?

Thanks,

John.

Attachments

-

46 KB Views: 52

-

17.9 KB Views: 76