greencardigan

Senior Member

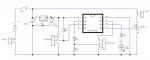

Hi,

I'm planning to use an 08M to control some 12V fans.

The 08M will read temp from DS18B20 and PWM fans via a FET.

Can anyone provide any comments on my circuit schematic or code.

Thanks,

Brad

I'm planning to use an 08M to control some 12V fans.

The 08M will read temp from DS18B20 and PWM fans via a FET.

Can anyone provide any comments on my circuit schematic or code.

Code:

symbol OFFTEMP = 432 'degrees x 16

symbol ONHALFTEMP = 448 'degrees x 16

symbol ONFULLTEMP = 464 'degrees x 16

symbol TEMP = w0

for b2 = 1 to 4 'flashes led

high 1

pause 20

low 1

pause 200

next

do

high 1 'flashes led on temp read

pause 20

low 1

readtemp 4, TEMP 'TEMP = degrees x 16

if TEMP >= ONFULLTEMP then

pwmout 2,0,0

high 2

else if TEMP >= ONHALFTEMP then

pwmout 2,255,600

else if TEMP <= OFFTEMP then

pwmout 2,0,0

endif

pause 5000

loopBrad

Attachments

-

36.3 KB Views: 116