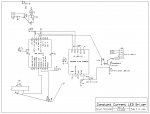

This is a constant-current LED driver I made using the Picaxe 18X, ADS1115 external I2C analog to digital converter, and an IGBT to do the switching. Wanted to make it so it fits into a light socket with a socket to outlet adaptor. I've determined the LEDs need more heat sink area than they currently have. After I built this I also learned (on here) about the benefit of using MOSFET drivers, especially at high PWM frequencies, and perhaps using an inductor on the output. I'm trying to figure out how to select the proper inductor value with the available PWM frequencies on Picaxe chips.

Code:

i2cslave %10010000,i2cfast, i2cbyte

pause 50

writei2c (%00000001,%01011110,%10000011)'config register

pause 50

writei2c (%00000010, $80,$00)

pause 5

writei2c (%00000011, $7F,$FF)

pause 5

writei2c (%00000000)

pause 50

w1 = 350

w2 = 450

start:

pwmout 3, 255, w1

gosub getcurrent

if w0 < w2 then

w1 = w1 + 1 max 1023

endif

if w0 > w2 then

w1 = w1 - 1 min 10

endif

'debug

goto start

getcurrent:

w0 = 0

w5 = 0

w6 = 0

writei2c (%00000000)

readi2c 0, (b1,b0)

returnAttachments

-

358.2 KB Views: 100

-

826.6 KB Views: 107

Last edited: