Hello.

I've been studying various animatronic projects and would like to set up a servo to respond to an adc input via a microphone. The idea would be to move a "jaw" up and down proportionately to the volume or length of time a voice was transmitted via a microphone. In other words, a long duration sound would move the servo to one end and hold it there (for the duration of the sound), a short sound would only move the servo slightly.

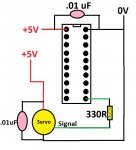

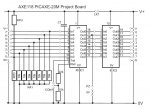

I've seen the excellent circuit to amplify an Electret Mic for the input side of the Picaxe but was wondering if the output to a servo can be controlled to the extent I'm looking for?

Hope I'm not sounding too stupid here.

Thanks.

I've been studying various animatronic projects and would like to set up a servo to respond to an adc input via a microphone. The idea would be to move a "jaw" up and down proportionately to the volume or length of time a voice was transmitted via a microphone. In other words, a long duration sound would move the servo to one end and hold it there (for the duration of the sound), a short sound would only move the servo slightly.

I've seen the excellent circuit to amplify an Electret Mic for the input side of the Picaxe but was wondering if the output to a servo can be controlled to the extent I'm looking for?

Hope I'm not sounding too stupid here.

Thanks.