The answer to this could be a long one.

Certainly more than 4 lines

Here is a short semi-answer to start you off.

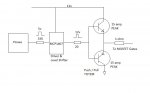

Switching a MOSFET would, from an ideal switching perpsective , be a perfect Zero-second transition.

This would keep the MOSFET out of that heat-generating (IsqR) area.

This is impossible and, as an aside, possibly have awful RFI/EMI implications.

So, we need to switch it at a suitable speed.

MOSFET switching in the Real World is often a compromise between heat efficiency and EMC performance - your switching losses and conductive losses. (Not loosses

)

Take a 50% duty at 10kHz; 50 microseconds (uS) on and ditto off.

Suppose your switching time was 10 uS you can see that this would be a significant proportion compared to the wave.

If you were to see this on a 'scope you'd see a trapezoidal wave rather than a perfect square.

If you could mathematically integrate those triangles with respect to Rds and V and measure Ids you could predict the heat generated.

No-one does this. You will see that the longer the slope (larger the triangles) the more heat is produced in the MOSFET.

Therefore, it is better (up to a point) to make those transitions as quick as possible.

If your switching was speeded up to 100nanoseconds the wave would be almost square.

The MOSFET would spend less time as a resistor and therefore stay cooler, but fast switching increases eletrical noise ... oh dear.

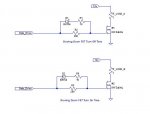

As you know, the Gate has capacitance but designers usually use the Charge value for basic calcs. as this removes the V bit for this first stage.

So, for example , the BUZ11 has 65nC of total Gate charge.

Suppose, for efficiency, you want to switch it in 500 nanoseconds (nS), you can calculate the peak current.

Remember, you are basically charging and discharging a capacitor so the current peaks then goes down exponentially,

You will know that Current (I) = Coulombs (C) per second (S).

Therfore you can now calculate the peak current to charge/discharge the gate in the desired amount of time.

On the other hand if your big fat MOSFET only needs to switch small currents then you will have to take this into account when doing your heat calcs.i.e. there may be less significance on trying to achieve fast switching. A balnce between Fq and I and switching speed.

I have attached a clunky Excel to get the initial ballpark figures.

Substitute your favourite cap values into it.

It's a bit messy (and eroneous in places) as I have been playing around with it but at least it'll start you off.

You should see that for fast switching the poor old PIC is way too small for fast switching. PIC will not happily drive that MOSFET at 10kHz.

Read the PDF I posted recently for general driving information, but there is tons available from various Manufacturers. IR produce some good stuff. Then look at Data Sheets for various I.C. drivers.

Spend a few weeks on it and you will get the answers to all your questions

OH, it won't let me upload Excel.

Oh well, I'm sure there's an on-line calculator somewhere.

Sorry, I'm afraid I can't give a 100% answer to your question.