Hi,

I have not had any luck trying to solve a problem with accurately measuring pulse width from R/C receivers (http://www.picaxeforum.co.uk/showthread.php?t=8410) so could I ask for YOUR help! If you have an oscilloscope and an r/c receiver (or other r/c-type signal source) could you please try the following:

1. Wire up a Picaxe chip (I'm using the 18X and 28X1 chips) so that the signal output from a channel on the r/c receiver goes into input 0 on the chip (mine have been mounted on the standard Picaxe Experimenter Board which is powered by the same 4.8 volt supply as the receiver). I you use an r/c receiver you may need to switch on the transmitter so that the receiver will generate a signal. I used a little servo testing gadget instead.

2. Program the Picaxe chip with this simple code:

3. Use the scope to examine the output from output 0.

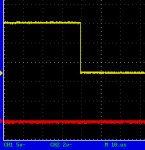

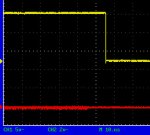

The signal should be rock solid but every time I try it the signal is read inconsistently causing the output to be correspondingly slightly unstable. If you get the same result you will see the signal on the scope vary slightly in length. This means that if I put a servo on the output it jitters slightly. It's odd because the rate of jitter varies. I have no idea why!

Obviously if you get the same problem as me the challenge is to try to fix it! You'll see from the other thread that I have tried all sorts of things to make it work, e.g. tying the outputs low with resistors etc. but nothing seems to work. I know I could smooth out the output with software but that is not an option as I have to make the servo as responsive as it is capable of being. It has to be a hardware solution.

PLEASE HELP!!!!

Many thanks,

Nigel

PS Here's my setup below...

I have not had any luck trying to solve a problem with accurately measuring pulse width from R/C receivers (http://www.picaxeforum.co.uk/showthread.php?t=8410) so could I ask for YOUR help! If you have an oscilloscope and an r/c receiver (or other r/c-type signal source) could you please try the following:

1. Wire up a Picaxe chip (I'm using the 18X and 28X1 chips) so that the signal output from a channel on the r/c receiver goes into input 0 on the chip (mine have been mounted on the standard Picaxe Experimenter Board which is powered by the same 4.8 volt supply as the receiver). I you use an r/c receiver you may need to switch on the transmitter so that the receiver will generate a signal. I used a little servo testing gadget instead.

2. Program the Picaxe chip with this simple code:

Code:

main: pulsin 0,1,w1

pulsout 0,w1

goto mainThe signal should be rock solid but every time I try it the signal is read inconsistently causing the output to be correspondingly slightly unstable. If you get the same result you will see the signal on the scope vary slightly in length. This means that if I put a servo on the output it jitters slightly. It's odd because the rate of jitter varies. I have no idea why!

Obviously if you get the same problem as me the challenge is to try to fix it! You'll see from the other thread that I have tried all sorts of things to make it work, e.g. tying the outputs low with resistors etc. but nothing seems to work. I know I could smooth out the output with software but that is not an option as I have to make the servo as responsive as it is capable of being. It has to be a hardware solution.

PLEASE HELP!!!!

Many thanks,

Nigel

PS Here's my setup below...

Last edited: