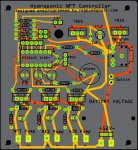

;NFT hydroponic controller to control water levels of tanks, running of NFT pump, refilling pump and air flow pump, change pumping times between daytime and nighttime, give warnings if main supply tank is low, indicat what function is active during use.

;coded for picaxe 14M2+ and use with an IBC as the NFT supply tank and connected to a rainwater tank for the reserve tank.

;change settings in start0 section to change the refilling time that is on after float switch toggles back. symbol filler_time.

;change settings in start1 level low section to change the pin values of NO or NC. Lines 61-62

; c.0 flashing red led hardware flash

; c.1 bulk tank sensor white leads input

; c.2 reserve tank sensor yellow leads input

; c.3 unused input only

; c.4 LDR input

; c.5 serial in programming

; b.0 sound

; b.1 flashing YELLOW LED hardware flash

; b.2 flashing GREEN LED sofware flash

; b.3 air pump

; b.4 refill pump

; b.5 nft pump

;symbol flash = 1 ;change for programs 2,3,4 [not used in this setup]

symbol F_Y_LED = B.2 ;flashing yellow led

symbol GRN_LED = B.1 ;green led software flash

symbol F_R_LED = c.0 ;reserve tank low warning

symbol NFT_pump = b.5

symbol AIR = b.3

symbol REFILLER = b.4

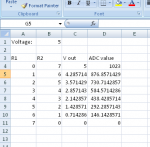

symbol DayTime = 100 ; LDR reading for day time threshold

symbol day_on = 45 ; 45 minutes

symbol day_off = 15 ; 15 minutes

symbol night_on = 5 ; 5 minutes

symbol night_off = 45 ; 45 minutes

symbol filler_time = 240 ;seconds, 4 minutes = 240 ideal for IBC tank, for smaller tank say 100L use about 30 seconds

start0: ;check level of NFT tank and turn on filling if needed and indicate condition.

do

if pinC.2 = 0 then ;float switch normally open, when closed trigger refilling

goto level_low

else

goto level_normal

endif

pause 100

loop

level_low:

high REFILLER ;switch refil pump on

low GRN_LED ;switch off green led while filling

high F_Y_LED ; turn on flashing yellow LED to indicate filling

;********************************************************************

for b4 = 1 to filler_time ; define 4 minutes in seconds CHANGE TO SUIT TANK SIZE

;********************************************************************

pause 1000 ; wait 1 second

next b4 ;keep from turning off the refill pump so that it does not start again too soon.

goto start0

level_normal:

low REFILLER ;switch refil pump off

low F_Y_LED ;switch off flashing yellow led

high GRN_LED pause 90 low GRN_LED pause 120 high GRN_LED pause 280 low GRN_LED pause 2000 ;switch on green led to show level normal

goto start0

start1: ; check reserve tank level and warn if low

;********************************************************************

if pinC.1 =1 then reserve_low ; white leads 1 for normally closed, 0 for normally open

if pinC.1 =0 then reserve_hi ;CHANGE TO SUIT FLOAT SWITCH

;********************************************************************

reserve_hi:

low F_R_LED ; turn off flashing red LED reserve tank normal

goto start1

reserve_low:

high F_R_LED ; turn on flashing red LED reserve tank low

pause 2000

sound 0, (119,50) ; sound warning

pause 200

sound 0, (119,50)

pause 200

goto start1

;--------------------------------------------------------------------------

start2:

b0 = 0 ; initialize b0 variable

main:

readadc C.4,b0 ; read LDR for night or day into variable b0

if b0 > 105 then Day

if b0 < 95 then nighttime

if b0 > 96 and b0 < 104 then waiting

goto done

Day:

low NFT_pump

for b9 = 1 to day_off

pause 60000 ; wait 60 seconds

readadc C.4,b0 ; read LDR for night or day into variable b0

if b0 < 95 then nighttime

if b0 > 96 and b0 < 104 then waiting

next b9

high NFT_pump ; turn off the pump

for b8 = 1 to night_off

pause 60000 ; wait 60 seconds

readadc C.4,b0 ; read LDR for night or day into variable b0

if b0 < 95 then nighttime

if b0 > 96 and b0 < 104 then waiting

next b8

goto main

nighttime:

high NFT_pump

for b9 = 1 to night_on

pause 60000 ; wait 60 seconds

readadc C.4,b0 ; read LDR for night or day into variable b0

if b0 > 105 then Day

if b0 > 96 and b0 < 104 then waiting

next b9

low NFT_pump ; turn on the pump

for b8 = 1 to night_off

pause 60000 ; wait 60 seconds

readadc C.4,b0 ; read LDR for night or day into variable b0

if b0 > 105 then Day

if b0 > 96 and b0 < 104 then waiting

next b8

waiting:

wait 6

readadc C.4,b0 ; read LDR for night or day into variable b0

if b0 > 105 then Day

if b0 < 95 then nighttime

if b0 > 96 and b0 < 104 then waiting

goto main

done:

goto start2

;---------------------------------------------------------------------------

start3: ; AIR control

let b1 = 0 ; initialize b0 variable

readadc C.4, b1 ; read LDR for night or day into variable b0

do

if b1 > 100 then

goto air_off

else

goto air_on

endif

loop

air_on: ; subroutine for air on and off repeating

high AIR

for b10 = 1 to 15 ; define on in minutes 15

pause 60000 ; wait 60 seconds

readadc C.4, b1 ; read LDR for night or day into variable b0

if b1 > 100 then

goto air_off

endif

next b10

low AIR ; air pump is off

for b11 = 1 to 15 ; define off in minutes 15

pause 60000 ; wait 60 seconds

readadc C.4, b1 ; read LDR for night or day into variable b0

if b1 < 100 then

goto air_on

next b11

endif

goto start3

air_off:

low AIR

goto start3