Hi.

Thanks for accepting me on the forum.

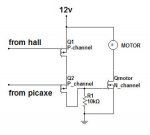

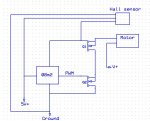

I have a problem and someone on another forum told me that a picaxe would solve it and redirected me here. I have a dc motor of my own making which I need to run under constant rpm under highly variable loads. My motors slows down when I give it bursts of power instead of continuous supply so I thought that I needed something to read the RPMs from a hall sensor, and if the RPMs go above the specified value, increase the frequency and decrease the duty cycle of the busts. If the RPMs drop below the specified value it should decrease the frequency and increase the duty cycle. I googled everything I could think of from but did not found anything that suits my needs. So I asked for help on electronics point forum and someone told me to get a picaxe (as I have no pic programmer) and thankfully provided a schematic. As the schematic suggested I got a 08m2 but now am in the difficult position to program the picaxe. I have never done any programming of any sort as i am only 16. I managed to do something in the logicator in flowchart format (attached bellow) but as you can see it only jumps from one state to the other instead of incrementally increase and decrease the frequency and duty cycle for example when the RPMs jump from 5000 (threshold value) to 5200 it should give 15khz 30% when the RPMS go 5500 it should give 20khz 20% and so on... My idea is to supply steady frequency that will correspond to 5000 RPMs from a function generator to C5 and the hall readings to C3 and get the output from C2…

Sorry if all that sound confusing but my English isn’t perfect.

Thank you for your time and tell me if you need more information.

Thanks for accepting me on the forum.

I have a problem and someone on another forum told me that a picaxe would solve it and redirected me here. I have a dc motor of my own making which I need to run under constant rpm under highly variable loads. My motors slows down when I give it bursts of power instead of continuous supply so I thought that I needed something to read the RPMs from a hall sensor, and if the RPMs go above the specified value, increase the frequency and decrease the duty cycle of the busts. If the RPMs drop below the specified value it should decrease the frequency and increase the duty cycle. I googled everything I could think of from but did not found anything that suits my needs. So I asked for help on electronics point forum and someone told me to get a picaxe (as I have no pic programmer) and thankfully provided a schematic. As the schematic suggested I got a 08m2 but now am in the difficult position to program the picaxe. I have never done any programming of any sort as i am only 16. I managed to do something in the logicator in flowchart format (attached bellow) but as you can see it only jumps from one state to the other instead of incrementally increase and decrease the frequency and duty cycle for example when the RPMs jump from 5000 (threshold value) to 5200 it should give 15khz 30% when the RPMS go 5500 it should give 20khz 20% and so on... My idea is to supply steady frequency that will correspond to 5000 RPMs from a function generator to C5 and the hall readings to C3 and get the output from C2…

Sorry if all that sound confusing but my English isn’t perfect.

Thank you for your time and tell me if you need more information.

Attachments

-

55.5 KB Views: 75