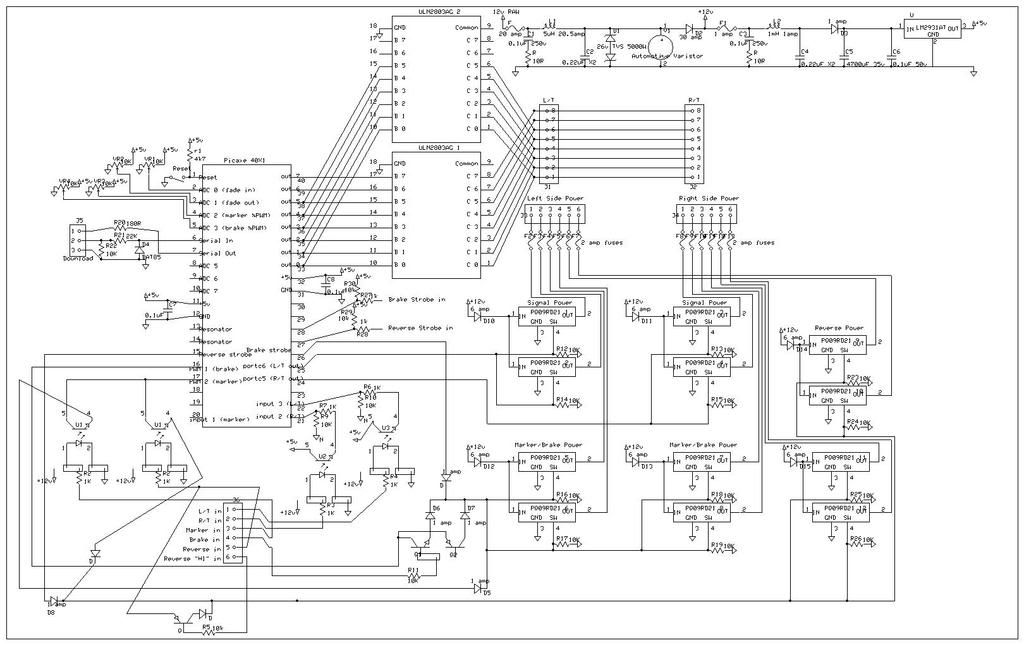

I haven't fully reviewed it myself yet, but it's been a while since I've posted about my project so I thought throw it up.. I've updated the schematic aswell.. but it's gotten somewhat messy now with all the changes.

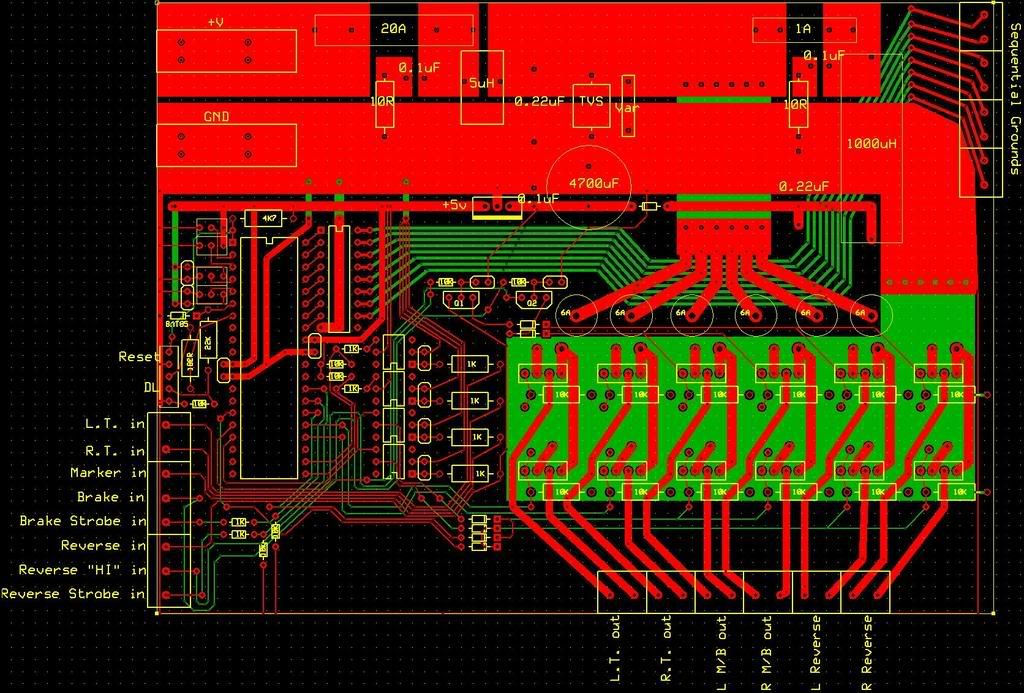

I've never designed a PCB before.. I tried not to daisy chain any power lines and pretty much just did what I thought was logical, I'm sure it's quite unorthodox.

I'm making the PCB myself, so I can't do plate through vias or anything, my 'vias' will just be wire soldered from one side of the board to the other.. in some places where I have resistors connecting from one layer to another I don't have this extra "via" because I figure I can just solder the lead from those resistors onto the top layer/component side (green) quite easily.. not something that would be as easy to do with DIP... hope that makes sense.

The design notes and updates include:

No code switching for the marker lights now.. the PWM signal will run constantly in the background and when the opto-isolator for the Markers is energized it will just conduct the PWM signal to the V-regs.. don't know why I just didn't do it that way before.

No jumpers for negative/positive switching.. it's all positive switched, I tested it out, so I might as well save the board space.

Brake strobe/Reverse strobe inputs are pulled high.. that way I can just run 1 wire to the front of the vehicle and ground it out to activate those inputs.

The LED reverse Lights I made are over 1000lumen each (bright than a 55w halogen headlamp) so they need to be dimmed for city use.. when reverse is activated the opto-isolator conducts the same PWM signal used for the Markers to the reverse lights.. Q1 is a PNP resistor that will be negatively switched up front (Reverse high in).. it takes the "reverse in" signal if present and just feeds it right to the V-regs for full brightness.

Q2 is an NPN transistor that conducts the brake PWM signal to the V-regs, I use a transistor here for faster switching of the brakes than an opto could provide.. trivial maybe.. more effective none-the-less.

I put 0.1uF caps on the inputs to the transistors and the opto-isolators.. I never had this in my schematic, but it seems like a good idea to stop noise from causing false triggers?.. I may use 0.01uF here as I have quite a few extras.. but I'll go with 0.1uF for the picaxe and such.

Something else I thought of I'd like to hear an opinion or 2 about.. should I use a 16V zener diode for the input to the NPN transistor? what about a regular diode on the PNP input?

The only place I ended up using wire links is on the #4 pins of the V-regs (they're upside down #4 is in the #1 position) to link them together.

So set me straight if I've gone astray here.. any input much appreciated

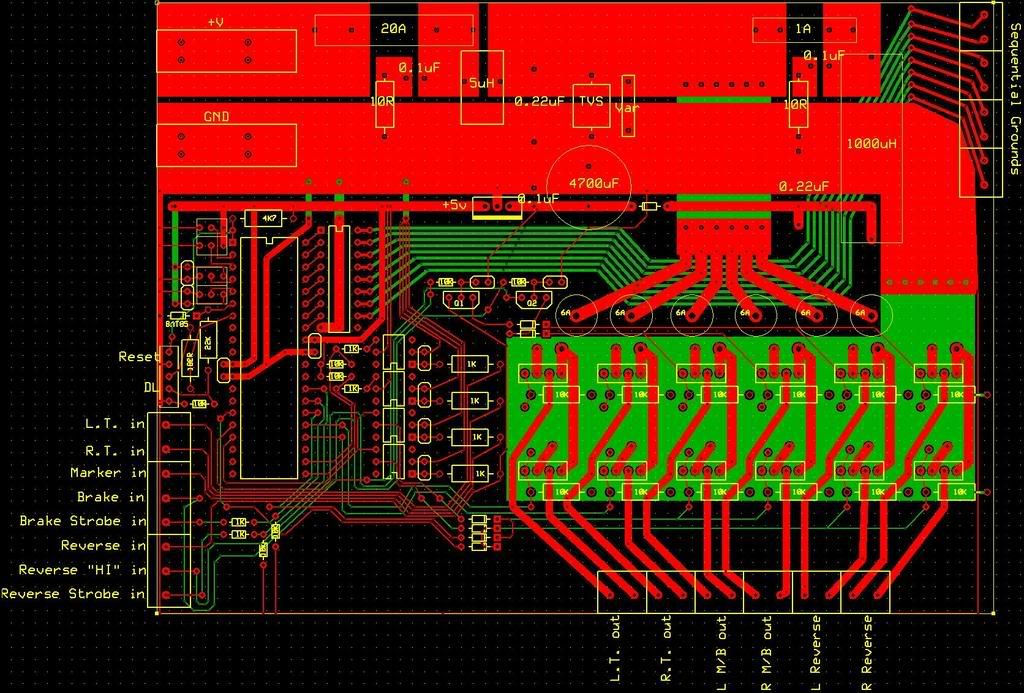

I've never designed a PCB before.. I tried not to daisy chain any power lines and pretty much just did what I thought was logical, I'm sure it's quite unorthodox.

I'm making the PCB myself, so I can't do plate through vias or anything, my 'vias' will just be wire soldered from one side of the board to the other.. in some places where I have resistors connecting from one layer to another I don't have this extra "via" because I figure I can just solder the lead from those resistors onto the top layer/component side (green) quite easily.. not something that would be as easy to do with DIP... hope that makes sense.

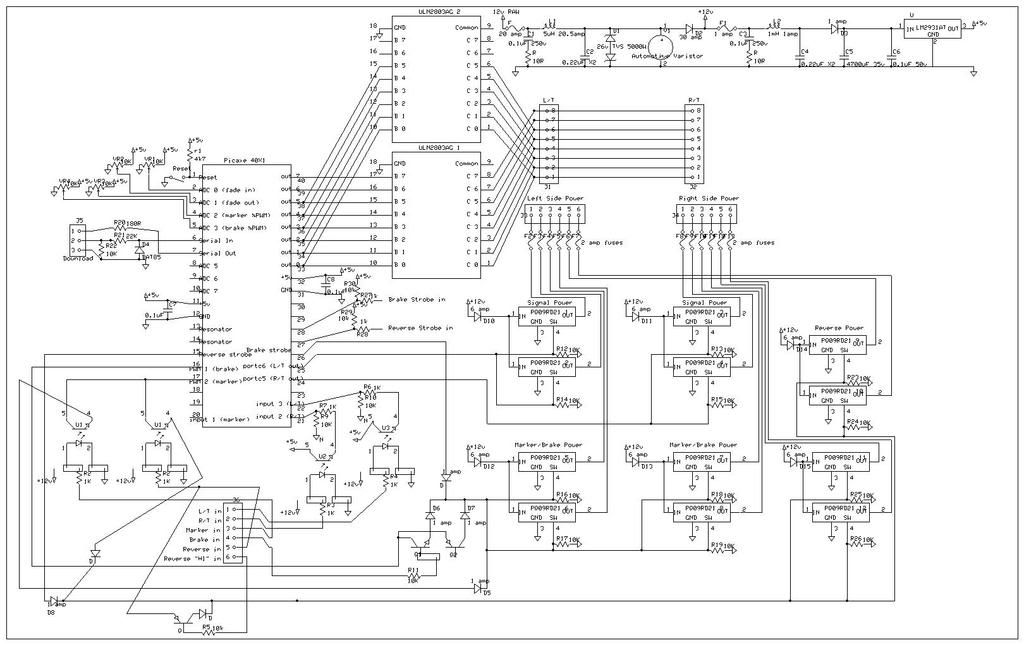

The design notes and updates include:

No code switching for the marker lights now.. the PWM signal will run constantly in the background and when the opto-isolator for the Markers is energized it will just conduct the PWM signal to the V-regs.. don't know why I just didn't do it that way before.

No jumpers for negative/positive switching.. it's all positive switched, I tested it out, so I might as well save the board space.

Brake strobe/Reverse strobe inputs are pulled high.. that way I can just run 1 wire to the front of the vehicle and ground it out to activate those inputs.

The LED reverse Lights I made are over 1000lumen each (bright than a 55w halogen headlamp) so they need to be dimmed for city use.. when reverse is activated the opto-isolator conducts the same PWM signal used for the Markers to the reverse lights.. Q1 is a PNP resistor that will be negatively switched up front (Reverse high in).. it takes the "reverse in" signal if present and just feeds it right to the V-regs for full brightness.

Q2 is an NPN transistor that conducts the brake PWM signal to the V-regs, I use a transistor here for faster switching of the brakes than an opto could provide.. trivial maybe.. more effective none-the-less.

I put 0.1uF caps on the inputs to the transistors and the opto-isolators.. I never had this in my schematic, but it seems like a good idea to stop noise from causing false triggers?.. I may use 0.01uF here as I have quite a few extras.. but I'll go with 0.1uF for the picaxe and such.

Something else I thought of I'd like to hear an opinion or 2 about.. should I use a 16V zener diode for the input to the NPN transistor? what about a regular diode on the PNP input?

The only place I ended up using wire links is on the #4 pins of the V-regs (they're upside down #4 is in the #1 position) to link them together.

So set me straight if I've gone astray here.. any input much appreciated

Last edited: