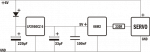

I am trying to control 2 brush-less motors with an 18m2+

I think the inputs may be out of the range required but they are limited to that so it may just be the mixing part

also think my limiters may not be working

I cant see why this wont work it is just getting an 18m2+ to mix two inputs for a motor output.

the first motor is always going full speed and the second gives me bad signal beeps (which I suspect is just telling me the throttle is to low)

any suggestions here's the code

View attachment t1 q v1 chp t.bas

I think the inputs may be out of the range required but they are limited to that so it may just be the mixing part

also think my limiters may not be working

I cant see why this wont work it is just getting an 18m2+ to mix two inputs for a motor output.

the first motor is always going full speed and the second gives me bad signal beeps (which I suspect is just telling me the throttle is to low)

any suggestions here's the code

View attachment t1 q v1 chp t.bas