GreenLeader

Senior Member

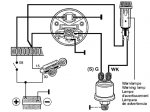

My car has a VDO electric oil pressure gauge. I would like to take (piggyback) the signal from the existing sensor into an an ADC on a Picaxe for logging.

Trouble is I don't understand the principle of operation of the gauge and have not been able to turn up much useful stuff on automotive instrumentation on the Internet.

The gauge spec is 0-100psi and 10-184 Ohms, and a schematic is attached. It has a switch output to drive a warning light and the analogue output to drive the gauge needle.

The question is: how can I get a voltage signal out of the sensor to log with a Picaxe ADC, without interfering with operation of the gauge?

Could anyone offer any tips?

Trouble is I don't understand the principle of operation of the gauge and have not been able to turn up much useful stuff on automotive instrumentation on the Internet.

The gauge spec is 0-100psi and 10-184 Ohms, and a schematic is attached. It has a switch output to drive a warning light and the analogue output to drive the gauge needle.

The question is: how can I get a voltage signal out of the sensor to log with a Picaxe ADC, without interfering with operation of the gauge?

Could anyone offer any tips?

Attachments

-

40.8 KB Views: 109