With a long cold winter ahead it seems automating and providing sensors for my old baler would be a nice project. While the total project is lengthy the individual pieces are small and simple enough to wrap my inexperience around.

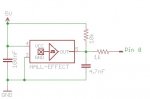

There are several bits of information to sense as a start. First is belt slippage, which can be calculated by comparing a drive roller with an idler roller. Two tachometers and a little math will do the trick. For the tachs I choose a Fairchild phototransistor reflective object sensor (QRB114). Not finding any info on connecting a transistor to a Picaxe input I simply used the switch input circuit, substituting the transistor. With a bit of tweaking on the diode side of the sensor the Picaxe (28X1) receives it. Later when I had time to search the whole web I found a couple of circuits, but so drastically different I need to ask which is the proper way. Attached are the 3 schematics, can anyone point me in the right direction?

There are several bits of information to sense as a start. First is belt slippage, which can be calculated by comparing a drive roller with an idler roller. Two tachometers and a little math will do the trick. For the tachs I choose a Fairchild phototransistor reflective object sensor (QRB114). Not finding any info on connecting a transistor to a Picaxe input I simply used the switch input circuit, substituting the transistor. With a bit of tweaking on the diode side of the sensor the Picaxe (28X1) receives it. Later when I had time to search the whole web I found a couple of circuits, but so drastically different I need to ask which is the proper way. Attached are the 3 schematics, can anyone point me in the right direction?

Attachments

-

18.9 KB Views: 64