Update:

I've been spending, don't tell the wife!!

Dremel 3000 plus pillar stand.

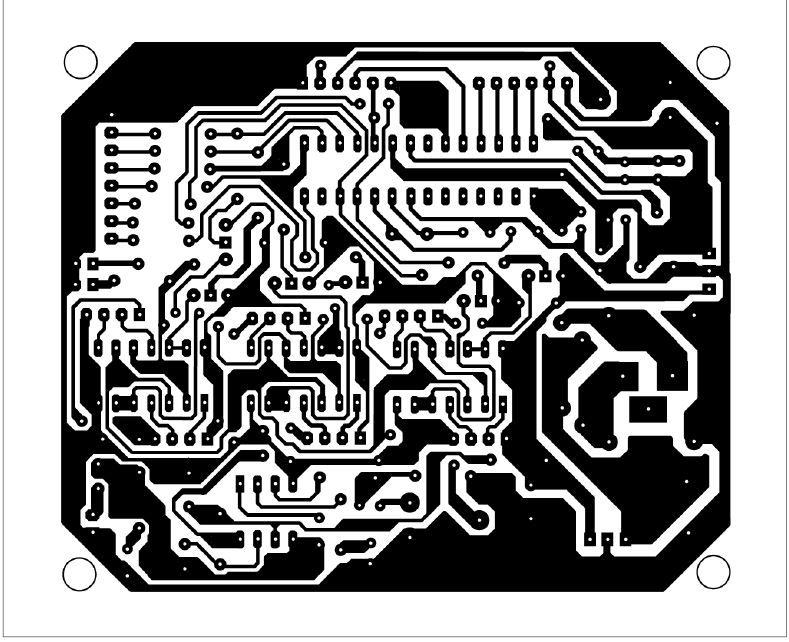

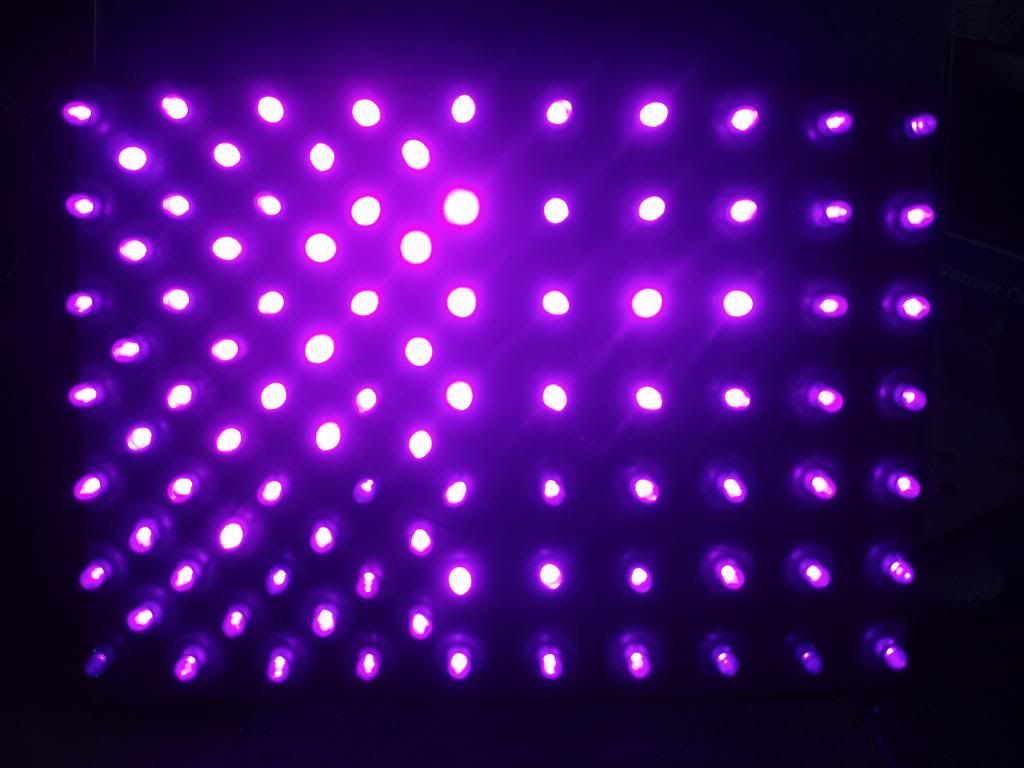

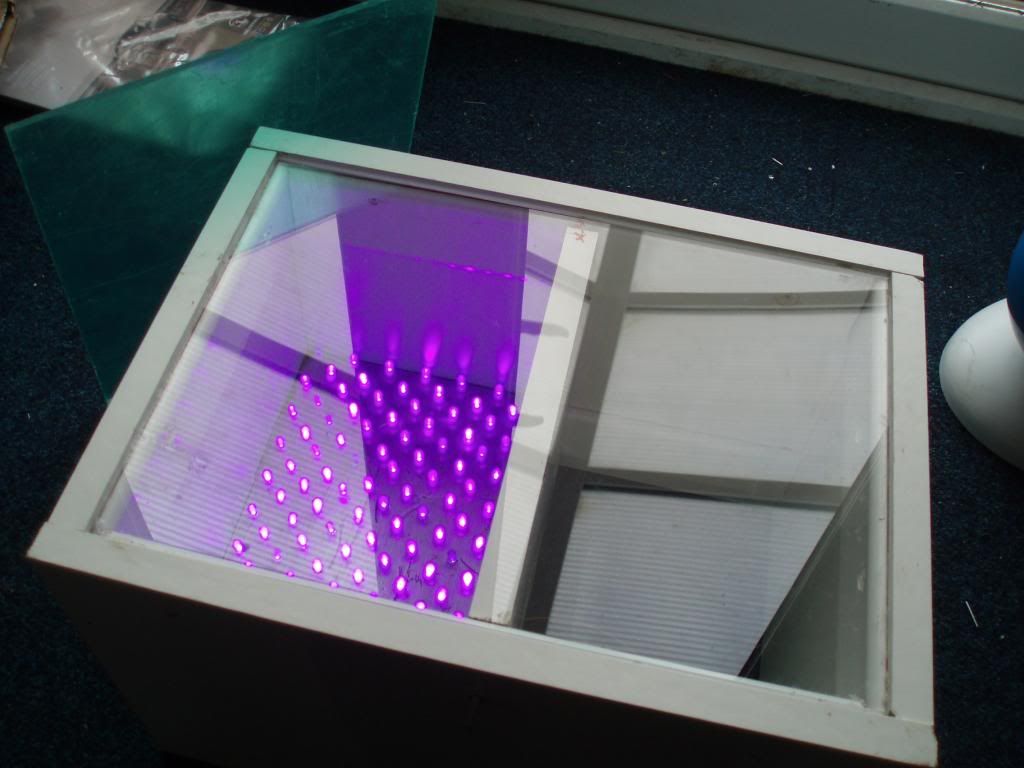

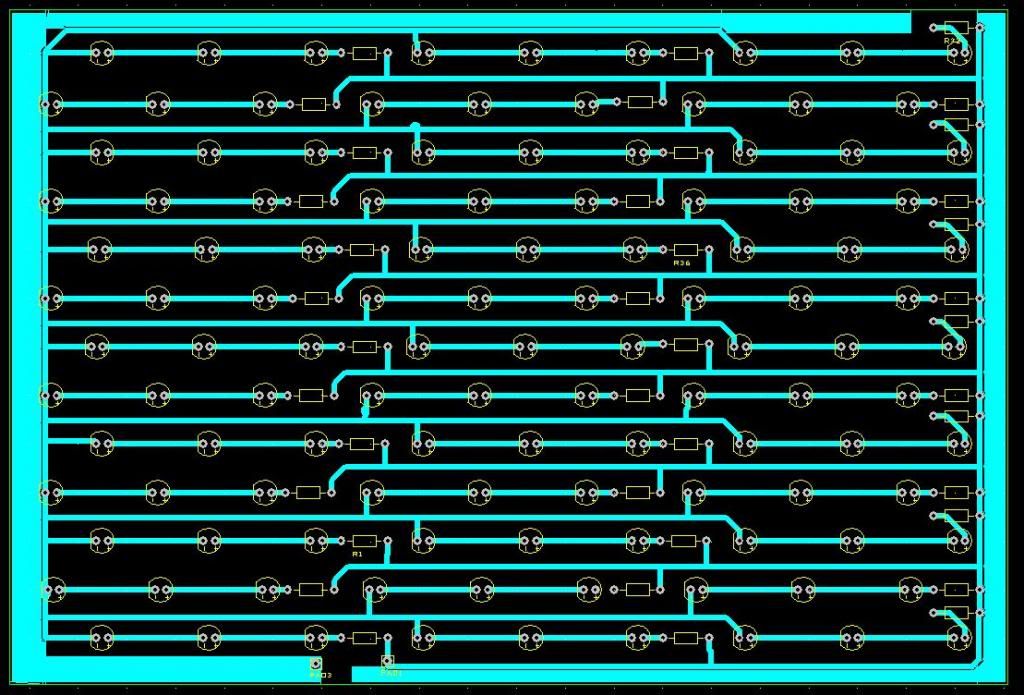

150 UV LED's, built into a contiboard box, timer via an old 18x picaxe and 2 thumbwheels.

bubble etching tank, 4ltr cereal plastic box, 3 fishtank bubble blocks, heated by 2kw fan heater pointed at the side of the tank, warms the workshop at the same time.

premium transparent film from Mega electronics, fotopcb from maplins.

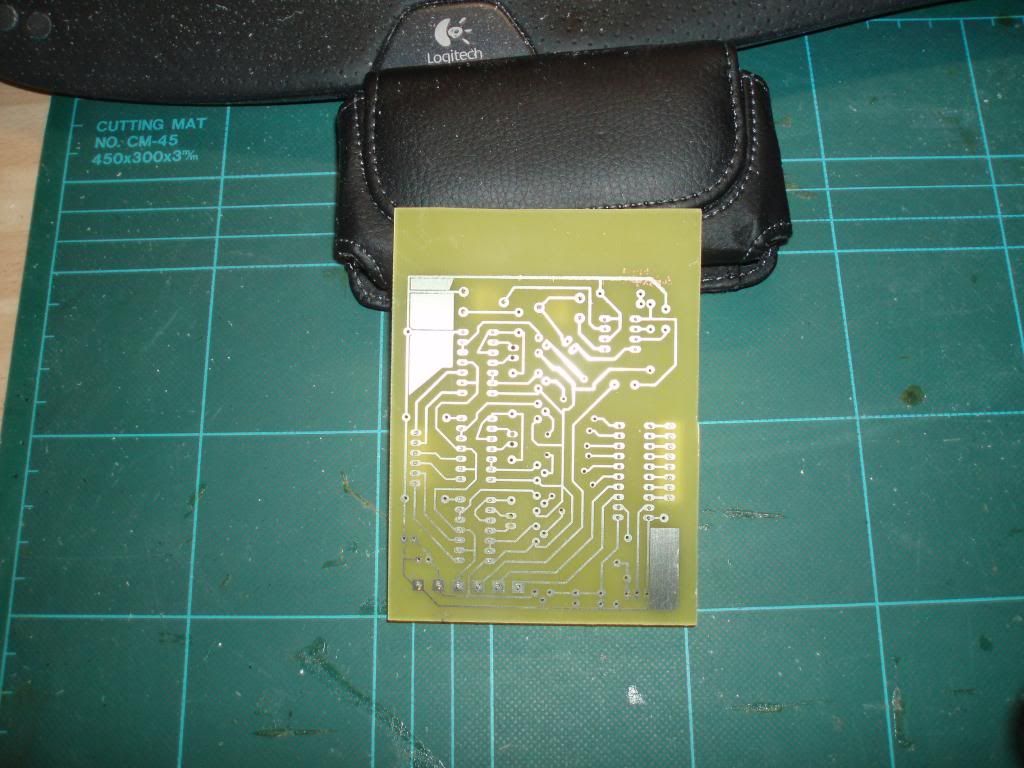

1st board, 5 mins uv exposure, 10-15 seconds developer, then etched till done.

perfect board, all tracks intact, no wispers, only problem was it was the wrong image, inverted...

2nd board, developed too long, nice clean copper board..

3rd board, as board 1 but correct way round.

The pillar drill and 0.8 / 1.0 collett drill bits are a must to get the holes properly aligned. turned pin sockets snapped straight into 0.8mm holes.

If anyone wants the construction of the UV box I'll put together a separate post.

TOF