Hi all,

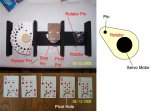

Just wanted to know if making an analogue clock was feasible or not by using two servos (for hands) and servo out on a loop.

Not made it, and don't even have the parts, just wondering if I won't waste time by writing a program and getting the parts.

I can imagine a digital clock being easier, but I would prefer to have it as an analogue clock, for presentation.

Comments?

Cheers

Just wanted to know if making an analogue clock was feasible or not by using two servos (for hands) and servo out on a loop.

Not made it, and don't even have the parts, just wondering if I won't waste time by writing a program and getting the parts.

I can imagine a digital clock being easier, but I would prefer to have it as an analogue clock, for presentation.

Comments?

Cheers