Hi

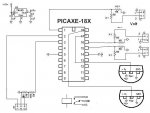

I'm trying to figure out if it is possible to collect data from a remote location and send commands the other way ie read temps etc and then if needed activate a relay

What i had in mind was a 08m at the remote end collecting data and send them via a 433 mhz wireless link to a basestation that displays the collected data, the base station should also hold a switch that could activate a relay at the remote end.

Getting the temps etc one way to base stations is simple enough, plenty of examples on that... its more to get the command for the relay the other way that are the trouble, for me at least

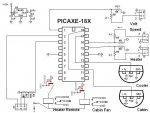

I'm trying to figure out if it is possible to collect data from a remote location and send commands the other way ie read temps etc and then if needed activate a relay

What i had in mind was a 08m at the remote end collecting data and send them via a 433 mhz wireless link to a basestation that displays the collected data, the base station should also hold a switch that could activate a relay at the remote end.

Getting the temps etc one way to base stations is simple enough, plenty of examples on that... its more to get the command for the relay the other way that are the trouble, for me at least