Bit of a newie question, sorry >___<

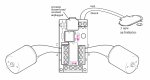

I have an AXE023 motor driver. I wanted to rig up 2 switches / buttons, and 2 Motors.

I later read the data sheet properly, after moving the jumpers around etc, and realised that you can only have either one motor and 2 switches, or 2 motors and one switch.

Does anyone know an easy hardware solution to have 2 motors (reverse and forward capable) and 2 switches all on the same board?

I need the smallest, cheapest option if possible.

The motors are small, and need to run off the picaxe power

I have an AXE023 motor driver. I wanted to rig up 2 switches / buttons, and 2 Motors.

I later read the data sheet properly, after moving the jumpers around etc, and realised that you can only have either one motor and 2 switches, or 2 motors and one switch.

Does anyone know an easy hardware solution to have 2 motors (reverse and forward capable) and 2 switches all on the same board?

I need the smallest, cheapest option if possible.

The motors are small, and need to run off the picaxe power