Making wire length cutting machine, need coding help *COMPLETED*

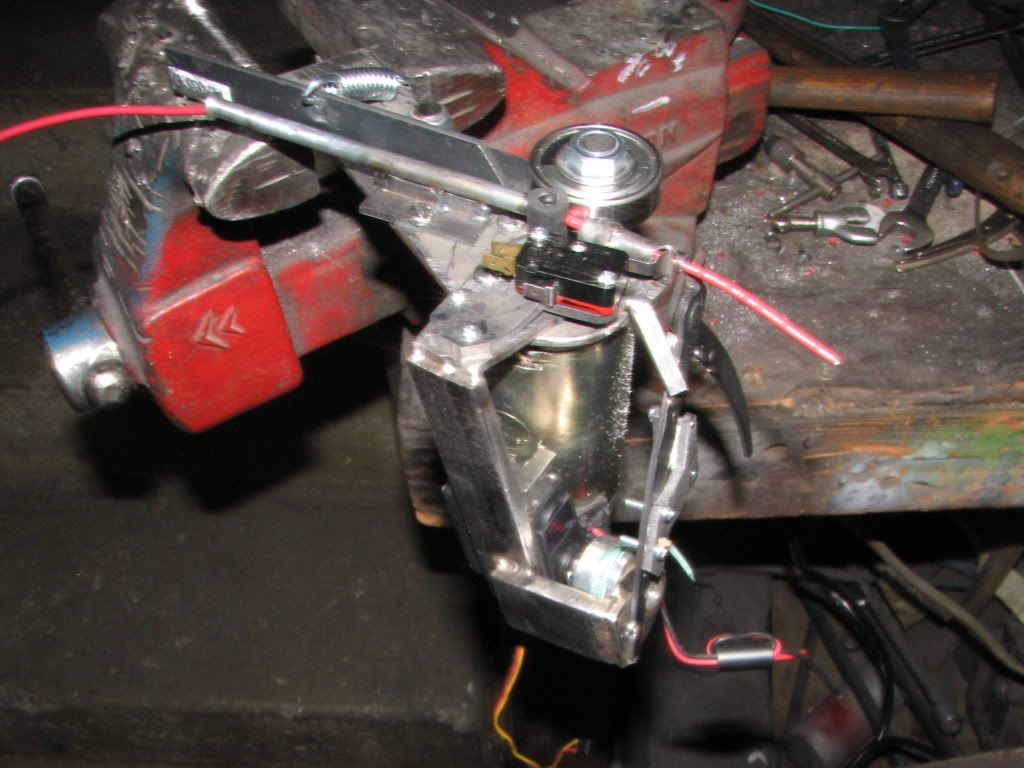

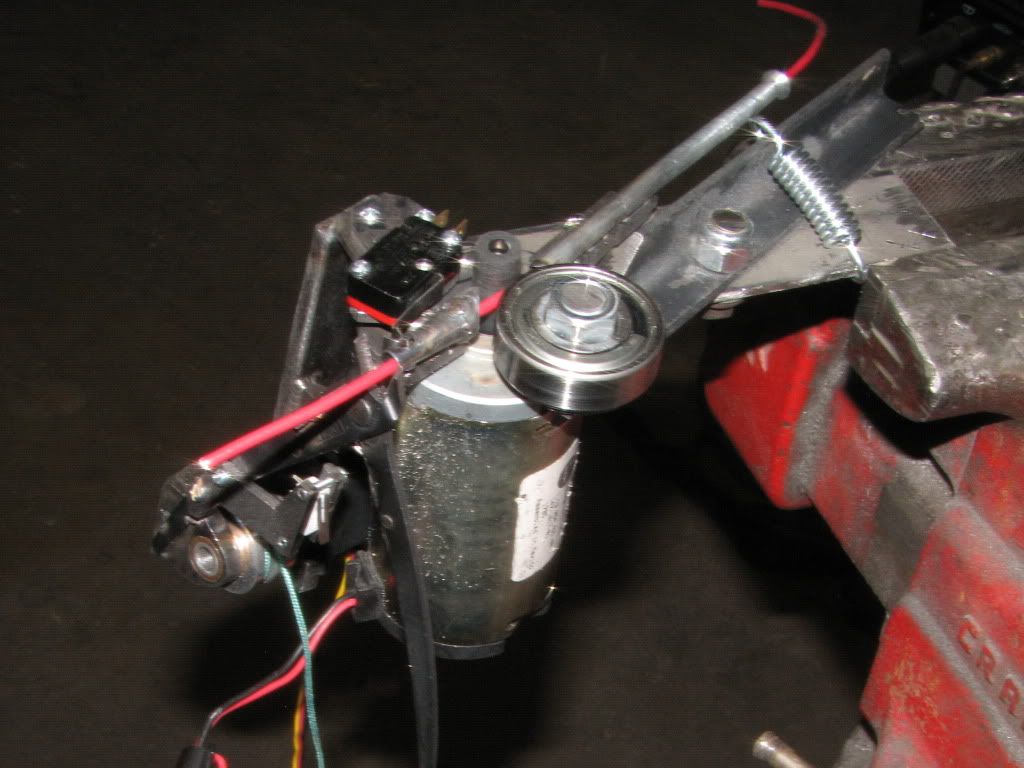

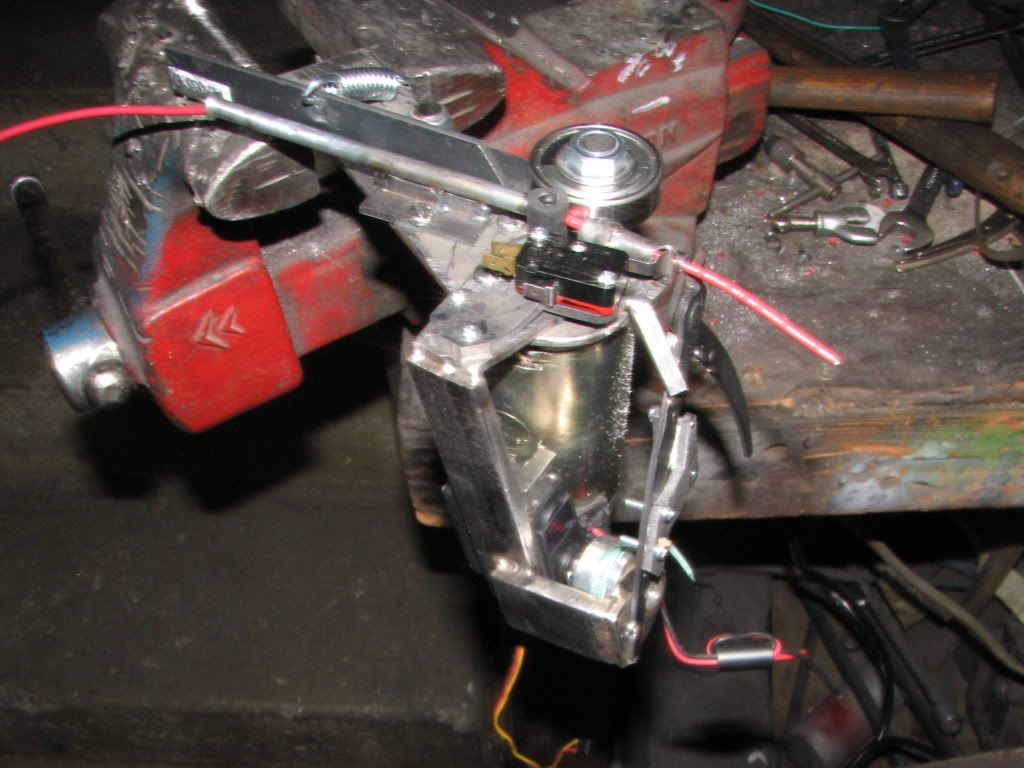

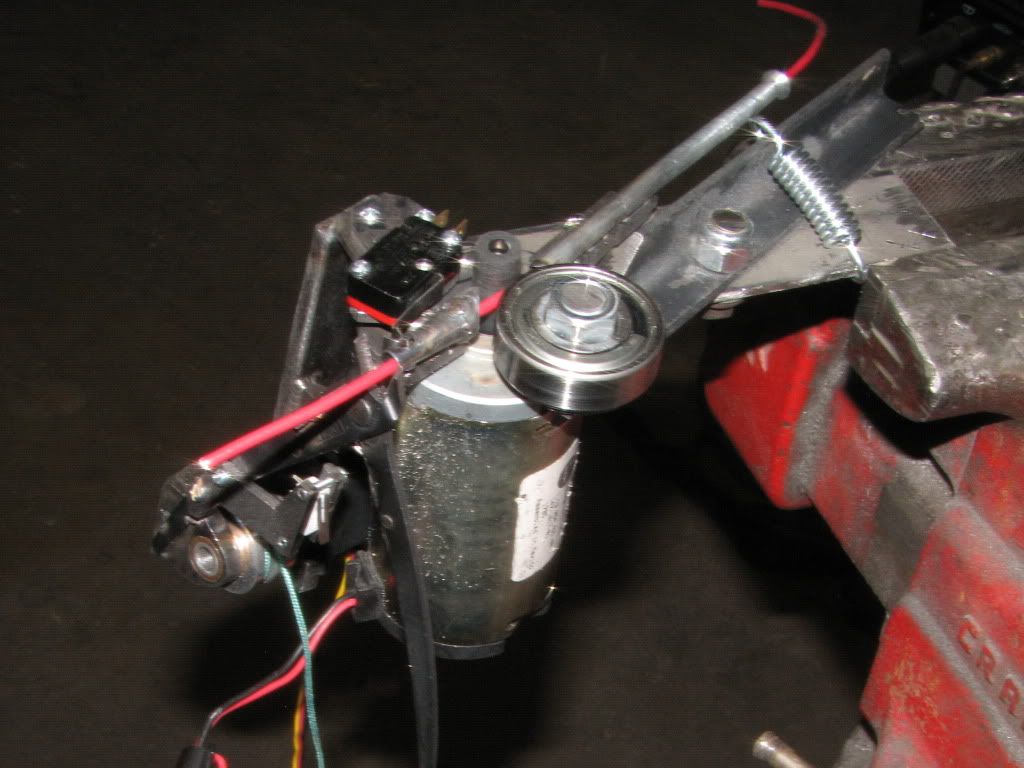

I'm making a machine that will quickly cut wire to length for me.

I'm basically done with the mechanical stuff now I need to start figuring out the and control software. I'm using a 28X2. Feed speed is quite fast, 2-4 feet per second.

Desired inches will be entered using a matrix keypad. The wire feeder will have a optical slotted disc to count pulses from the drive wheels. The entered inches will be converted into a target number of pulses.

I need to figure out the coding that will immediately brake the feed motor (with a high output) when the target number of pulses are seen.

Any ideas?

Can I use the 'count' command with a long time period and have an output go high as soon as the word variable fills up to the proper amount? Since I don't know how long it needs to count (different lengths of wire etc.) will it just sit there for the remained of the time duration?

I'm making a machine that will quickly cut wire to length for me.

I'm basically done with the mechanical stuff now I need to start figuring out the and control software. I'm using a 28X2. Feed speed is quite fast, 2-4 feet per second.

Desired inches will be entered using a matrix keypad. The wire feeder will have a optical slotted disc to count pulses from the drive wheels. The entered inches will be converted into a target number of pulses.

I need to figure out the coding that will immediately brake the feed motor (with a high output) when the target number of pulses are seen.

Any ideas?

Can I use the 'count' command with a long time period and have an output go high as soon as the word variable fills up to the proper amount? Since I don't know how long it needs to count (different lengths of wire etc.) will it just sit there for the remained of the time duration?

Last edited: