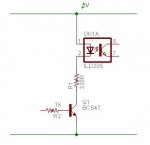

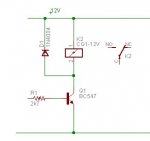

I'm having a problem with my circuit (schematic below). This circuit is an electric match ignition system with continuity check. GPA0 is an input, which reads the continuity circuit. GPA0 is an output, which activates the relay that will allow current to flow into the electric match, igniting it.

For some reason the relays are closed (turned on) when I send a 0/low signal to them, and open (turned off) when I send a 1/high signal to them.

This is problematic because everything pulses whiles the circuit is starting up. As I am running an electric match off this circuit, it would let the firework off everytime I turned the circuit on!

The other problem is that the continuity check circuit is 0/low when there is continuity, and 1/high when there is no continuity (eg when there is not electric match attached).

I must have gone wrong somewhere with my circuit. How do I switch these low/high states around?

Any help appreciated!!

[size=+3]ATTENTION:[/size] This circuit is NOT complete and therfore NOT safe.

For some reason the relays are closed (turned on) when I send a 0/low signal to them, and open (turned off) when I send a 1/high signal to them.

This is problematic because everything pulses whiles the circuit is starting up. As I am running an electric match off this circuit, it would let the firework off everytime I turned the circuit on!

The other problem is that the continuity check circuit is 0/low when there is continuity, and 1/high when there is no continuity (eg when there is not electric match attached).

I must have gone wrong somewhere with my circuit. How do I switch these low/high states around?

Any help appreciated!!

[size=+3]ATTENTION:[/size] This circuit is NOT complete and therfore NOT safe.

Last edited: