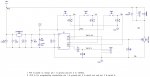

Attached is the code and the schematic for my 12V motor controller. When I press the button on C.1, the motor runs fast, and when I press the button on C.4, the motor runs slowly, and when no buttons are pressed, the motor stops. That's all good, but when I press the button on C.3, the motor makes a stuttering noise and doesn't turn. Can anyone tell me where to look for the mistake? Thanks.

Attachments

-

38 KB Views: 31

-

181.4 KB Views: 30

Last edited: