marzan

Senior Member

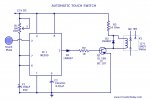

Hi everyone. I have a floor lamp that uses a 200W halogen bulb and I am thinking of converting it to a few LED arrays. I want to power it with a 12v wall wart. it is metal so I was thinking of making it a touch lamp. When looking into using the touch sensor on an 08M2 I read that it dosen`t actually work by touch, so can anyone point me in the right direction to find some sort of circuit diagram to connect to a picaxe ? I want to use the PWM function to have about 4 different levels of light. I had a look on Google and couldn`t really find anything that looks like it would hook up to a picaxe.

Thanks.

Marz.

Thanks.

Marz.