Mycroft2152

Senior Member

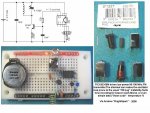

My latest PICAXE / DIPTRACE project is interfacing with Veecad, a stripboard layout program.

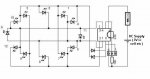

Veecad requires a separate schematic editor to generate netlists. Then matches the components frrom Veecad's footprint library and does the stripboard layout.

It's a pretty clever program and under $25US.

I'm curious how many forum members use the stripboarding techinique. So chime in if you do!

I don't expect many responses from US forum members, as stripboardss are pretty much unheard of in the US and are difficult to buy.

Thanks,

Myc

Veecad requires a separate schematic editor to generate netlists. Then matches the components frrom Veecad's footprint library and does the stripboard layout.

It's a pretty clever program and under $25US.

I'm curious how many forum members use the stripboarding techinique. So chime in if you do!

I don't expect many responses from US forum members, as stripboardss are pretty much unheard of in the US and are difficult to buy.

Thanks,

Myc

![pRS1C-2265164w345[1] (Small).jpg](/data/attachments/1/1042-ade14397f368ae88780ba13e83ff596a.jpg)