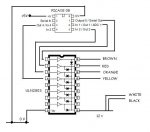

I am using a ULN2803 darlington array and a picaxe 08 to drive a stepper.

I have managed to get it to turn but it seems like there is almost zero torque. Just lightly touching it with my finger will stop it.

The motor was advertised as a 12v 1.8 degree step. The datasheet does not seem to have the exact model number shown on the motor..

Stepper: shinano STP-42D241 , datasheet for the STP42 series: http://www.shinano.com/xampp/docs/SST42D.pdf

I am powering it with a 12 volt, 300mA rated wall wart.

I determined the motor wiring by connecting various wires to the multimeter, set to ohms:

orange/brown: 6

orange/black: 3

brown/black: 3

red/yellow: 6

red/white: 3

white yellow: 3

Can anyone spot any errors? Maybe this is a 24 v motor and my power supply is just weak. The voltage on the supply actually reads higher than 12, more like 15 volts.

Thank you

I have managed to get it to turn but it seems like there is almost zero torque. Just lightly touching it with my finger will stop it.

The motor was advertised as a 12v 1.8 degree step. The datasheet does not seem to have the exact model number shown on the motor..

Stepper: shinano STP-42D241 , datasheet for the STP42 series: http://www.shinano.com/xampp/docs/SST42D.pdf

I am powering it with a 12 volt, 300mA rated wall wart.

I determined the motor wiring by connecting various wires to the multimeter, set to ohms:

orange/brown: 6

orange/black: 3

brown/black: 3

red/yellow: 6

red/white: 3

white yellow: 3

Code:

stepdemo:

for b0=1 to 10 'CW rotation

pulsout 0,5000: pause 10 ' Pin 0

pulsout 1,5000: pause 10 ' Pin 1

pulsout 2,5000: pause 10 ' Pin 2

pulsout 4,5000: pause 10 ' Pin 4

next b0

for b1 = 1 to 10 'C-CW rotation

pulsout 4,5000: pause 10 ' Pin 4

pulsout 2,5000: pause 10 ' Pin 2

pulsout 1,5000: pause 10 ' Pin 1

pulsout 0,5000: pause 10 ' Pin 0

next b1

goto stepdemoCan anyone spot any errors? Maybe this is a 24 v motor and my power supply is just weak. The voltage on the supply actually reads higher than 12, more like 15 volts.

Thank you

Attachments

-

27.1 KB Views: 52