premelec

Senior Member

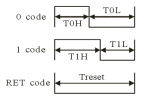

It appears that the frequency required to drive this one wire RGB chip may be too high for PICAXE to retrieve data and make up drive pulses though I'm not too clear on just what is necessary from the data sheet [other than zeros are short pwm and ones are long pwm pulse]. It did occur to me that perhaps one could make up a fake MP3 file which would have the required pulse characteristics and trigger playing that to the WS2812 but I have not a clue how one would do that... Has anyone successfully driven this chip with a PICAXE? Which chip? [I looked in this forum but found no conclusive answer..] Thanks for any help or telling me it can only be done with external components...