Hi

New to this electronics game and forum.

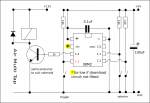

I have made this circuit to control an Airsoft gun I am building, see attachment

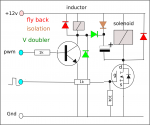

The circuit controls the opening and closing of the solenoid valve and how long it stays open and closed.

It will have 3 different fire modes, controlled by a select lever, still to be designed.

Note the car battery is for testing and will be replace with lipo (11.1 or 18 volt).

I have some questions I am hopping to get sorted.

The circuit works as intended, but.

The AA's fire the solenoid ok, but, when connected to an air supply they will fire it only for a short time.

Disconnect the air the solenoid will fire

I assume the AAs just don't have enough power to drive the TIP142T is this correct?

I have thought of replacing the AA's with a 3.6 lipo telephone battery, would this last longer?

A combined power source is another option, but I don't know how to do this.

As noted in the attachment I had to change some parts, because of availability, could these be causing problems?

I did have the input jumper set to programe, would that drain the power?

If there is an easier way to do this project please let me know

Thanks for your time an comments

Derek

New to this electronics game and forum.

I have made this circuit to control an Airsoft gun I am building, see attachment

The circuit controls the opening and closing of the solenoid valve and how long it stays open and closed.

It will have 3 different fire modes, controlled by a select lever, still to be designed.

Note the car battery is for testing and will be replace with lipo (11.1 or 18 volt).

I have some questions I am hopping to get sorted.

The circuit works as intended, but.

The AA's fire the solenoid ok, but, when connected to an air supply they will fire it only for a short time.

Disconnect the air the solenoid will fire

I assume the AAs just don't have enough power to drive the TIP142T is this correct?

I have thought of replacing the AA's with a 3.6 lipo telephone battery, would this last longer?

A combined power source is another option, but I don't know how to do this.

As noted in the attachment I had to change some parts, because of availability, could these be causing problems?

I did have the input jumper set to programe, would that drain the power?

If there is an easier way to do this project please let me know

Thanks for your time an comments

Derek