Hi,

I have been reading several forum threads to try and understand how a remote (as for outside the house and away from mains electricity) WiFi connected temperature sensor could operate without the need to change or remove the batteries for recharging.

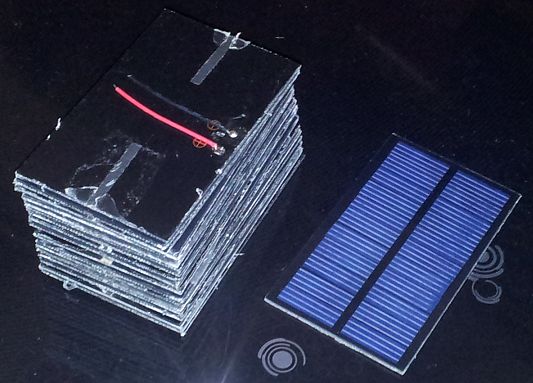

One obvious choice would be to use a solar panel and rechargeable batteries. I have committed the usual “click before you spec” sin and I am now the proud owner of a small solar panel, which may not be suitable, but I could buy a different one it necessary.

There is a lot of information on the forum and I was able to gain awareness of issues to consider, but I would like some guidance on how to put it all together. My question is about what the main building blocks of this system would be.

My thinking is outlined below:

The payload:

• Picaxe + ESP8266 + DS18B20

• Transmitting every 30 minutes for a minute (wake up, connect, transmit, go to sleep)

• Current usage when transmitting ~200-250 mA

Energy sources:

1) Solar panel, from China, nominal specs below:

• Operating voltage: 6V

• Working current 0.33A

• Open circuit voltage 7.2V

• Short circuit voltage: 0.38A

2) Single 3.2VLiFePO4 battery (AA size, they have about 700 mAh capacity)

I did some calculations on the energy needs and the suitability of the panel

• Average current = 6.5 mA (200 mA for a minute every 30 minutes)

• Daily usage: 6.5 * 24 = 156 mAh

• Weekly usage: 156 * 7 = 1092 mAh

• Charging efficiency (circuitry + chemistry) = 10% (assumed)

• Weekly solar panel charge requirement: 10920 mAh

• Daily charging hours (average) = 10920 / 0.33 / 7 = 4.7 --> need a bigger panel?

My questions are:

1) Do I need a bigger panel?

2) Is a single LiFePO4 cell enough to power the payload?

3) I presume I need a board to manage the charging. Would this one be suitable?

http://www.ebay.co.uk/itm/181728713087?_trksid=p2055119.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

I also saw this website www.talkingelectronics.com but, for the price, the board above is hard to beat

4) Do I need to control the charger with the Picaxe or can I let the charger board do it “unsupervised”?

5) Can I power the Picaxe with the battery while charging? Will I need a voltage regulator downstream of the battery (hopefully not)?

6) Will I need to implement a battery discharge protection?

7) What other issues should I consider?

It is a long list of questions, I know, but hopefully the answers it will not be useful to me. Also, happy to read other threads if this has been discussed before.

Many Thanks

Riccardo

I have been reading several forum threads to try and understand how a remote (as for outside the house and away from mains electricity) WiFi connected temperature sensor could operate without the need to change or remove the batteries for recharging.

One obvious choice would be to use a solar panel and rechargeable batteries. I have committed the usual “click before you spec” sin and I am now the proud owner of a small solar panel, which may not be suitable, but I could buy a different one it necessary.

There is a lot of information on the forum and I was able to gain awareness of issues to consider, but I would like some guidance on how to put it all together. My question is about what the main building blocks of this system would be.

My thinking is outlined below:

The payload:

• Picaxe + ESP8266 + DS18B20

• Transmitting every 30 minutes for a minute (wake up, connect, transmit, go to sleep)

• Current usage when transmitting ~200-250 mA

Energy sources:

1) Solar panel, from China, nominal specs below:

• Operating voltage: 6V

• Working current 0.33A

• Open circuit voltage 7.2V

• Short circuit voltage: 0.38A

2) Single 3.2VLiFePO4 battery (AA size, they have about 700 mAh capacity)

I did some calculations on the energy needs and the suitability of the panel

• Average current = 6.5 mA (200 mA for a minute every 30 minutes)

• Daily usage: 6.5 * 24 = 156 mAh

• Weekly usage: 156 * 7 = 1092 mAh

• Charging efficiency (circuitry + chemistry) = 10% (assumed)

• Weekly solar panel charge requirement: 10920 mAh

• Daily charging hours (average) = 10920 / 0.33 / 7 = 4.7 --> need a bigger panel?

My questions are:

1) Do I need a bigger panel?

2) Is a single LiFePO4 cell enough to power the payload?

3) I presume I need a board to manage the charging. Would this one be suitable?

http://www.ebay.co.uk/itm/181728713087?_trksid=p2055119.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

I also saw this website www.talkingelectronics.com but, for the price, the board above is hard to beat

4) Do I need to control the charger with the Picaxe or can I let the charger board do it “unsupervised”?

5) Can I power the Picaxe with the battery while charging? Will I need a voltage regulator downstream of the battery (hopefully not)?

6) Will I need to implement a battery discharge protection?

7) What other issues should I consider?

It is a long list of questions, I know, but hopefully the answers it will not be useful to me. Also, happy to read other threads if this has been discussed before.

Many Thanks

Riccardo

Last edited: