Hello!

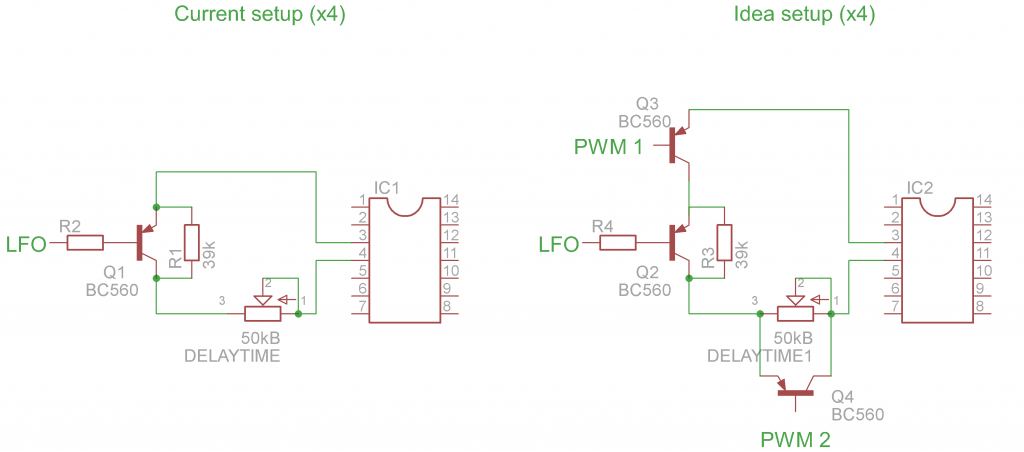

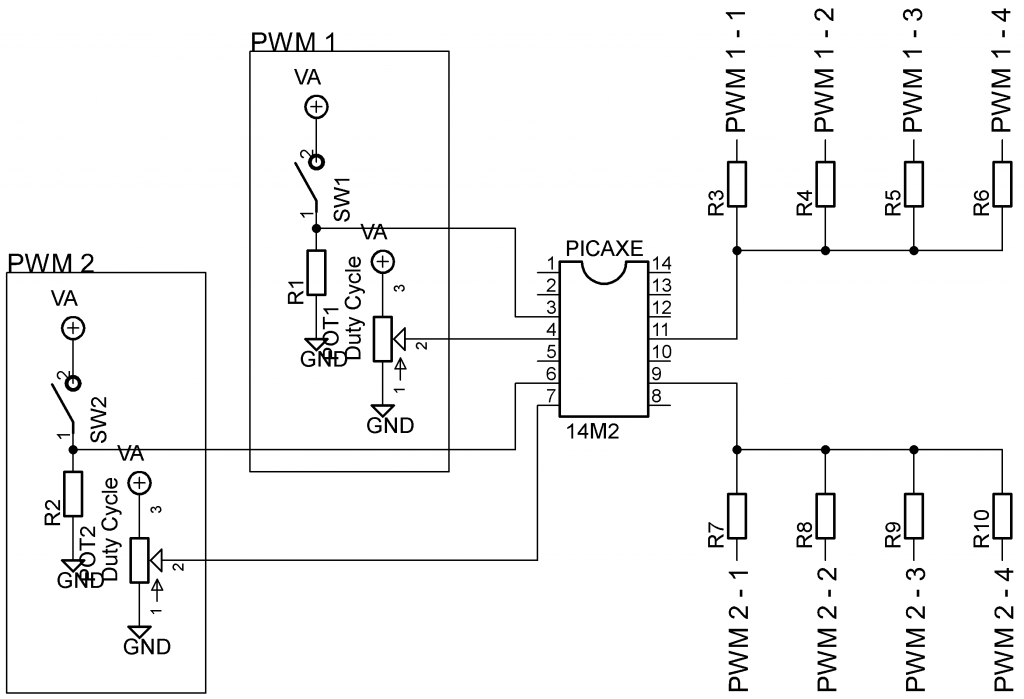

I'm working on an idea currently (code to come later, if the idea fleshs out well) for using the PWM out of the PICAXE to the base of a BC560 (or similar) transistors acting as a current controlled resistors. There are many levels of things I don't understand, so I'll start with the basic idea of the project.

Eight transistors in total are being used as the current controlled resistors. In normal operation of the device, four of them will be held high in saturation for the least resistance and the other four will be held low for infinite (I guess? or at least very large) resistance by the PWM. There are four interfaces for a user - two switches and two potentiometers. When one button is pushed and held, the transistors held high will begin to decrease in voltage as the PWM slows at a rate that is defined by the definition of the pot. The other pot and switch act in the same way, but it increase the transistor up to saturation. Upon release of a button, the PWM goes back to its normal rate at a speed based off of the speed at which it changes (most likely faster, but related to the initial speed). Both buttons will not be expected to operate at the same time, but both PWM signals need to be constantly running.

As I said, there are many levels I don't understand. The PICAXE can read the two buttons inputs on two pins by applying 5V when pushed. Two seperate pins can read the potentiometer value, but I don't know how to apply that to the rate of the PWM, if at all possible? The PWM should probably also be constrained between just below the turn on current/voltage of the transistor (so their isn't dead space at the bottom of the PWM wave) and the max 5V. I've seen projects where LED's are set to pulse/dim with the PWM, but I'm not sure how to drag that out into this project.

Some other confusions: is it possible to use a current mirror and power all four transistors off of one pin of the PICAXE? That way an 14M2 can be used instead of something much larger with 8pwm outputs (I believe the 08M2 only has 1 pwm output?). Is it even possible to have two different PWM's coming from the same chip, or will I need to use two 08M2's? Does anyone have better ideas

Thank you for lending your amazing brain powers.

I'm working on an idea currently (code to come later, if the idea fleshs out well) for using the PWM out of the PICAXE to the base of a BC560 (or similar) transistors acting as a current controlled resistors. There are many levels of things I don't understand, so I'll start with the basic idea of the project.

Eight transistors in total are being used as the current controlled resistors. In normal operation of the device, four of them will be held high in saturation for the least resistance and the other four will be held low for infinite (I guess? or at least very large) resistance by the PWM. There are four interfaces for a user - two switches and two potentiometers. When one button is pushed and held, the transistors held high will begin to decrease in voltage as the PWM slows at a rate that is defined by the definition of the pot. The other pot and switch act in the same way, but it increase the transistor up to saturation. Upon release of a button, the PWM goes back to its normal rate at a speed based off of the speed at which it changes (most likely faster, but related to the initial speed). Both buttons will not be expected to operate at the same time, but both PWM signals need to be constantly running.

As I said, there are many levels I don't understand. The PICAXE can read the two buttons inputs on two pins by applying 5V when pushed. Two seperate pins can read the potentiometer value, but I don't know how to apply that to the rate of the PWM, if at all possible? The PWM should probably also be constrained between just below the turn on current/voltage of the transistor (so their isn't dead space at the bottom of the PWM wave) and the max 5V. I've seen projects where LED's are set to pulse/dim with the PWM, but I'm not sure how to drag that out into this project.

Some other confusions: is it possible to use a current mirror and power all four transistors off of one pin of the PICAXE? That way an 14M2 can be used instead of something much larger with 8pwm outputs (I believe the 08M2 only has 1 pwm output?). Is it even possible to have two different PWM's coming from the same chip, or will I need to use two 08M2's? Does anyone have better ideas

Thank you for lending your amazing brain powers.